November 6, 2025

by Alexandra Vazquez / November 6, 2025

by Alexandra Vazquez / November 6, 2025

Inventory is the heartbeat of any product-based business.

It’s what connects supply to demand, and production to profit. Whether it’s raw materials waiting to be assembled or finished goods ready to ship, inventory is what keeps operations moving.

Inventory refers to the goods, materials, or products a company holds for the purpose of resale or production. It includes raw materials, work-in-progress items, and finished goods. Managing inventory efficiently is crucial to meeting demand, minimizing costs, and ensuring smooth operations.

Inventory is considered one of the most important assets for a company. This is because inventory is indirectly a significant revenue source. On a balance sheet, the value of inventory is labeled as a current asset until the product is distributed and moved to cost of goods sold (COGS).

Most businesses utilize inventory management software to organize their inventory. Inventory solutions help companies gather real-time inventory analytics, budget for purchasing materials, predict future needs using stock data history, and integrate automated inventory management tools.

Companies will accumulate many types of inventory items for the production process. There are four main types of inventory most companies have on hand, plus a few others that are not as common, but still valuable.

Raw materials are all the essential items needed to create whatever good you offer. This includes items that will eventually be part of the finished product or any materials needed along the way. There are two different types of raw materials: direct and indirect.

Direct raw materials specifically help build the final product. The cost of direct materials is easily measured and budgeted because companies can determine their direct raw material needs in conjunction with the number of products they create.

Tracking and reporting the costs of direct materials is especially important because it directly impacts the price of the final product and its market value. An example of direct raw materials is the fabric used to produce a clothing line.

Indirect raw materials are still necessary for production, but are not necessarily part of the final product. Indirect raw materials are more challenging to budget for because they aren’t necessarily on a one-to-one basis with products created.

This makes tracking and reporting costs more complicated and not as linear as direct materials. An example of indirect materials is the sewing machines used to put together the fabric in the production of a clothing line.

Some companies use materials management to streamline the way they organize their materials. Materials management controls how materials move through the supply chain and ensures all necessary materials are available to create the final product. Some companies also use a batch inventory management system to keep track of perishable raw materials, or to perform a product recall should something go wrong with their items.

Work in progress (WIP), or work in process, inventory is made up of items that are currently utilized in production. This inventory may include raw materials, but the difference lies in where the materials are in the production process. As soon as those raw materials are used, they’re part of a company’s WIP inventory.

An example of WIP inventory is the wood used to create a coffee table. Once the wood is cut or dyed, it’s considered a work-in-progress item.

Finished goods inventory comprises all the items that make it through the entire production process and are considered finalized products. These products have been inspected and are ready to be sold.

For example, a piece of art is not truly complete until the paint is dry. Once it’s hung in a gallery with a price assigned, it’s considered a finished good.

Maintenance, repairing, and operating (MRO) inventory is all of the small materials used throughout the production process that don’t end up being part of the final product. This includes anything used to fix, assemble, or organize the goods.

An example of MRO inventory is the gloves used by warehouse employees assembling the product. Another example is the computer used to count inventory items and create reports.

The following types of inventory are not used by every company, but are still beneficial to the production process.

From raw materials to finished goods, tracking inventory accurately is key. Discover the best inventory control software on G2 to gain real-time visibility and keep your stock under control.

You know the saying, “you don’t know what you got until it’s gone”? When it comes to inventory, you don’t know what you got until you spend way too much time looking for it.

is the estimated value of the global inventory optimization market in 2025.

Source: Coherent Market Insights

Inventory affects whether production and distribution will be successful before it even begins. Although it may seem somewhat indirect, inventory has a huge impact on overall company revenue.

Think about it this way: inventory = products, products = sales, sales = profits.

An organized inventory is efficient. The faster items are found and used in production, the faster products are made. Tracking inventory is essential for making sure the process runs smoothly.

Inaccurate inventory causes significant setbacks and delays the order fulfillment process. Allocating more time to organize inventory creates fewer opportunities for error and reduces the chances of losing or misplacing items. That's why it's important to have efficient inventory management that results in effective order fulfillment.

The more organized the inventory system is, the faster it moves through production. Customers are happy when they get their orders on time. They’re even happier when they get their item faster than anticipated. This kind of satisfaction attracts loyal customers and positive organic publicity.

Success starts at the very beginning of the production process. The outcome of your inventory offers a lot of information.

Excess inventory creates spoilage and means that demand is not prospering as usual. Insufficient inventory creates stockouts and means your company is not keeping up with supply demands. You can determine if you have excess or insufficient inventory by calculating your inventory at the end of your accounting period.

Ending inventory = beginning inventory + net purchases - cost of goods sold

You can help save time and money and prepare for customer demand more effectively by adjusting inventory levels based on your findings and forecasting inventory needs.

A disorganized inventory space can cause major problems in the production and distribution process. Any problem that creates setbacks and delays has a cost attached.

For example, simply misplacing inventory items will cause the production process to halt. It also means that the money spent on those lost items essentially goes down the drain. Tracking inventory effectively will help you avoid those losses.

On top of cutting costs, accurate inventory counts can help allocate existing finances more effectively. Keeping a close eye on inventory will uncover needs that aren’t being met. That information can help your company use your budget to its fullest potential.

All inventory needs are different; inventory management methods will look different for every company, too. There are four inventory management types you can use to optimize your inventory.

It keeps track of inventory continuously. Inventory is updated in real time as items move through the production process. This method is favored by stakeholders, retailers, and business owners because the metrics are constantly updated. However, many labor costs are incurred when inventory is manually kept.

It allocates specific time intervals to update inventory. Companies model these intervals after their accounting periods. Implementation of this system is straightforward because it requires little to no technology. However, similar to the perpetual system, human error is a concern.

The barcode inventory system uses barcode technology to track and update inventory. The barcodes are customized to match specific inventory categories. Items are scanned as they move through the supply chain, so inventory counts are updated almost instantly. Some companies may find implementing the barcode system tedious because every item needs a unique barcode.

This uses tags that emit radio signals with inventory data. The tags can hold a lot of identifying information about the item, including descriptions, counts, uses, and more. The radio signals help track the amount of inventory items and their location within the space. Although it saves a significant amount of time, implementing and maintaining an RFID system is costly.

Companies use a few formulas to calculate the best way to restock their inventory and prepare for future needs.

It calculates a company’s ideal quantity of materials to fulfill the necessary number of products using historical data. You can calculate your EOQ by gathering data on customer demand, setup costs, and holding costs.

EOQ = √(2DS ÷ H)

D = demand

S = setup costs (packing, shipping, delivery)

H = holding costs (warehousing, insurance, storage)

It calculates when an inventory item should be repurchased based on previous sales cycles. This formula can be applied to every SKU and relies on identifying patterns.

Reorder point = (average daily unit sales x delivery lead time) + safety stock

It estimates how many days it takes for inventory to eventually turn into sales. DIO helps companies measure success in their inventory efficiency. For this formula, a lower output is favorable.

Days inventory outstanding (DIO) = (average inventory ÷ cost of goods sold) x number of days in a cycle

It helps companies calculate how much backup inventory they need. This formula helps companies avoid overstocking and understocking by finding a good average for emergency inventory.

Safety stock = (maximum daily usage x maximum lead time in days) - (average daily usage x average lead time in days)

There are a few ways that companies can organize existing inventory. All of these methods help make the inventory process more efficient, although some are more favorable than others, depending on what products you sell and how you store and use materials.

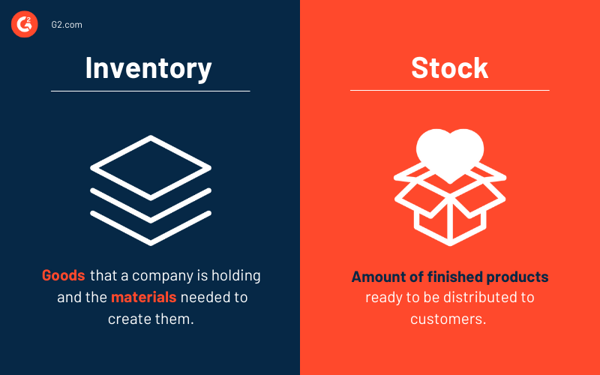

Inventory and stock are often used interchangeably, but hold different meanings depending on the context. They differ in their use cases, value, and costs.

Inventory includes all the finished goods created by a company plus the materials and components needed to develop the products. Inventory is noted on a company’s balance sheet as an asset. The cost of purchased materials calculates the valuation of inventory.

Stock refers to the number of finished goods that have reached point of sale (POS) and are ready for distribution. Stock is noted in overall business profit records as it contributes to final revenue. Inventory helps determine the final cost of stock by tracking the average cost incurred while creating it. The market selling price determines its value.

Essentially, stock is always inventory, but inventory is not always stock. This is because stock levels can refer to products held by a company that are ready to sell, therefore it falls under the inventory umbrella. On the other hand, inventory is used in production and unavailable to sell directly to customers, so it’s not stock.

Assets and inventory are also often confused. Companies eventually sell inventory to create a profit, while assets help them use and manage inventory.

For example, inventory is the materials needed to create a product, and assets are the equipment used in production as well as the property where it takes place. In many cases, companies report their inventory as a current asset.

There are a few things to keep in mind as you build and optimize your inventory. These best practices outline ways to level up your inventory process, ensuring smooth production for you and a positive experience for your customers.

Got more questions? We have the answers.

Inventory is a current asset because it's expected to be sold, used, or converted to cash within a year. Until sold, it sits on the balance sheet; once sold, it becomes cost of goods sold, directly affecting revenue.

The right method depends on your business size, product type, and inventory complexity. Use periodic systems for simplicity, perpetual systems for real-time tracking, or just-in-time (JIT) if you want to minimize holding costs and rely on demand forecasting.

Safety stock is extra inventory held to prevent stockouts from demand spikes or supplier delays. It ensures you can continue fulfilling orders even when unexpected disruptions occur.

Key metrics include inventory turnover, days inventory outstanding, carrying cost, stockout rate, and order accuracy. These help you evaluate efficiency, cost control, and fulfillment reliability.

Poor inventory management can lead to stockouts, overstock, lost sales, production delays, and excess costs. Over time, it impacts cash flow, customer satisfaction, and profitability.

Manufacturers manage raw materials and WIP inventory to support production. Retailers focus on finished goods and sales-ready stock. Each requires different systems and priorities to match operational goals.

Inventory is a direct driver of revenue, efficiency, and customer satisfaction. Whether you're managing raw materials, in-progress items, or finished goods, how you track, organize, and optimize inventory can make or break your operations.

By understanding inventory types, choosing the right management methods, and applying key formulas, businesses can reduce waste, prevent stockouts, and stay agile in a shifting market. But even the best strategy needs the right tools to execute.

Ready to take control of your inventory? Explore the best inventory control software on G2 to discover top-rated platforms and find the solution that fits your business needs.

This article was originally published in 2022. It has been updated with new information.

Alexandra Vazquez is a former Senior Content Marketing Specialist at G2. She received her Business Administration degree from Florida International University and is a published playwright. Alexandra's expertise lies in copywriting for the G2 Tea newsletter, interviewing experts in the Industry Insights blog and video series, and leading our internal thought leadership blog series, G2 Voices. In her spare time, she enjoys collecting board games, playing karaoke, and watching trashy reality TV.

Remember Veruca Salt's unforgettable demand in Willy Wonka: “I want it now!” Today's shoppers...

by Deirdre O'Donoghue

by Deirdre O'Donoghue

Decoding the retail puzzle for businesses.

by Téa Liarokapi

by Téa Liarokapi

What comes to mind when you hear the term “real estate”?

by Izabelle Hundrev

by Izabelle Hundrev

Remember Veruca Salt's unforgettable demand in Willy Wonka: “I want it now!” Today's shoppers...

by Deirdre O'Donoghue

by Deirdre O'Donoghue

Decoding the retail puzzle for businesses.

by Téa Liarokapi

by Téa Liarokapi