October 14, 2025

by Alexandra Vazquez / October 14, 2025

by Alexandra Vazquez / October 14, 2025

Before the first pallet hits the floor, or another inefficiency eats into your margins, it’s time to ask: Is your warehouse layout helping or holding you back?

If you’re preparing to expand, streamline fulfillment, or upgrade to automation, layout planning isn’t just a facilities decision; it’s an operational strategy. Whether you’re retrofitting an existing space or mapping out a new site, the way you design your warehouse will directly shape throughput, labor cost, picking speed, and order accuracy.

Think of your layout as the infrastructure behind every operational KPI. When it’s built to align with your business goals and optimized through the right tools, your team can fulfill faster, scale smarter, and make fewer mistakes, all without adding headcount or square footage.

For companies reaching an inflection point, growth, automation, SKU expansion, and a modern warehouse layout, supported by a robust warehouse management software becomes a high-ROI investment. Done right, it’s not just about floor space; it’s about turning your warehouse into a competitive advantage.

A warehouse layout is the arrangement of storage areas, equipment, and work zones within a warehouse to maximize efficiency, safety, and flow of goods. A good layout reduces travel time, improves inventory access, and supports faster order fulfillment.

But it's not just about where things go. A smart layout determines how goods flow through each stage of your operation, from receiving to storage, picking, packing, and outbound shipping. When optimized, your warehouse layout supports better productivity, minimizes travel time, and reduces errors.

A good warehouse layout should improve the flow of your facility. But there are many more things a warehouse layout can do to enhance the way you operate. These objectives contribute to the main purpose of keeping costs down and productivity up. Here are some goals that an effective warehouse layout will help you reach.

The most significant objective of a warehouse layout is to optimize the way warehouse space is used. Using warehouse space effectively allows companies to reduce the time it takes to produce a product and get it out the door, gain visibility into what is and isn’t working in the warehouse, and organize inventory to streamline the process at every stage.

Every inch of a warehouse should be utilized to its fullest potential. Being well-versed in the warehouse area and size is critical because your chosen layout will impact how much you achieve in the space overall.

Every company wants to improve productivity and speed up order fulfillment without sacrificing quality. The right warehouse layout design aims to optimize operations while reducing the chances of bottlenecks or errors.

of survey respondents took their business elsewhere when they were notified that an item was out of stock after placing an order.

Source: Stitchlabs

Warehouse management teams work closely with operations management teams to ensure production runs smoothly from start to finish and orders are fulfilled effectively.

Depending on existing warehouse floor space, some layouts may be more expensive to create and sustain than others. Finding a suitable layout means becoming very aware of what materials are available and where staff will fall into place.

Once the right warehouse layout starts to come into effect, companies can allocate resources more efficiently. This includes using budgets for warehouse maintenance and hiring the right amount of employees to carry out the processes in an environment where they can thrive.

As simple as it sounds, keeping things tidy can help to avoid significant issues within the warehouse. The right warehouse floor plan should reduce the chances of items being misplaced or mishandled, as everything has its place within the flow of operations.

When everything runs efficiently, all of your warehouse operations will be set up for success. A warehouse layout contributes to the big picture of warehouse management in creating an environment where inventory is organized, stock is replenished quickly, staff is treated fairly, and orders are fulfilled.

There are a few major areas that need to be included in a warehouse design. These areas are used to hold inventory, organize stock, prepare items for shipping, and receive items to be arranged within the warehouse system.

Each warehouse flow has five main components it houses:

Once you’ve collected the necessary information and goals, you can determine which warehouse layout meets your needs. The flow of a warehouse relies heavily on the space available and how things will move within the overall operations.

There are three main types of warehouse layout flows that companies use to organize the way their warehouse operates: U-shaped, I-shaped, and L-shaped.

There is no underdog when it comes to warehouse flows. All are helpful in their own ways, and finding the right fit comes down to which one works with what you currently have and hope to achieve.

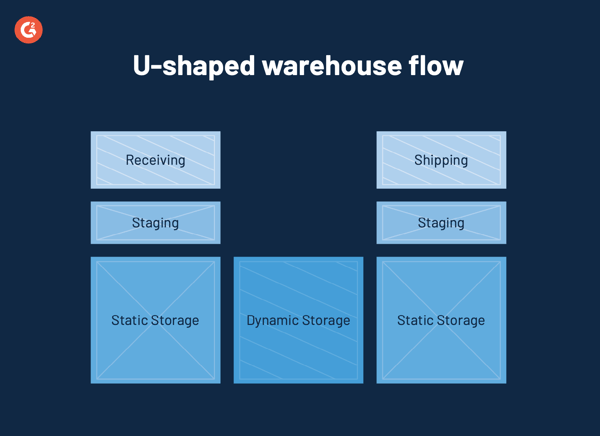

The U-shaped warehouse flow is the most common of the three. It has been recognized as the best layout for warehouse beginners. All components are arranged in a semicircle with shipping and receiving on parallel sides and storage in the middle.

The U shape is used to keep major warehouse traffic flow separate and streamlined. Keeping the incoming and outgoing materials on parallel sides of the operation helps to avoid bottlenecks. This flow of goods is also helpful in minimizing the available space necessary. With both the entrance and the exit sharing the same side of the building, less space is needed for packages, and employees can quickly move products between receiving and shipping.

A disadvantage of the U-shaped flow is that production congestion can occur when shipping and receiving areas are close together and share similar domains.

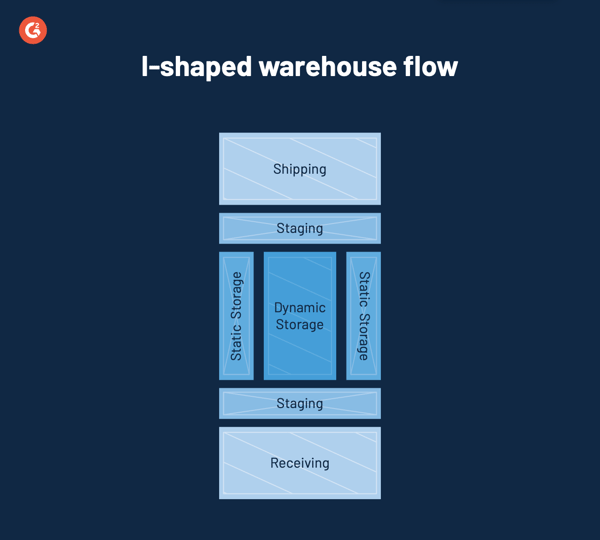

The I-shaped warehouse flow is favored by large corporations with bigger warehouses. This is because larger companies typically experience higher production volume, and the I shape is valuable for its clear in and out workflow.

The I-shape warehouse design has a straight flow from receiving to shipping and vice versa. This setup is said to increase optimization the most as it uses the entire length of the warehouse, keeps similar products separated in an assembly-line format, and minimizes bottlenecks by avoiding back and forth movements.

The disadvantages of the I shape are that companies need to have optimal loading and unloading space on two sides of the warehouse building. Costs may increase when purchasing docking equipment for the inbound and outbound areas, and goods often need to travel the entire length of the warehouse to reach their intended destination.

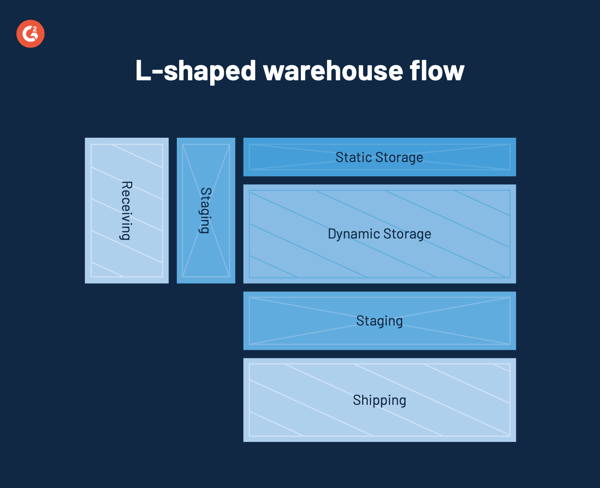

The L-shaped warehouse flow is considered the least common of the flow types. Its configuration is very unusual and is generally chosen to specifically accommodate an L-shaped building.

The L shape features the shipping area on one side and the receiving on the adjacent side at a 90-degree angle. The L-shaped flow and I-shaped flow are relatively similar in their advantages.

The L shape also minimizes congestion by avoiding back-and-forth movement and effectively separates products with inbound and outbound docks on opposite sides. The most significant disadvantage of the L-shaped design is how much space is needed to run this flow effectively.

There are many factors to examine when choosing the right layout for your warehouse. The processes below should be considered when determining space requirements and the most suitable layout for your desired warehouse.

Once you know all the pieces that need to come together in your warehouse, you can start making moves towards actually designing your ideal warehouse layout. Your warehouse layout design should include all the necessary areas that your facility requires, while utilizing every inch of usable space.

Before actually making any decisions regarding the warehouse setup, take time to create a visual aid you can use to play around with the available space. This includes marking where shipping and receiving docks can fit, keeping in mind how many trucks you hope to fill at a time. A well-designed layout will help to avoid being one of the 160k truck accidents that occur every year and avoid costly delays. This blueprint will help you see your warehouse as a blank canvas.

After creating a blueprint of the warehouse and collecting measurements, you can start planning how different warehouse components can be set up. This includes offices, employee spaces, dynamic storage, static storage, staging areas, and shipping and receiving docks. All major areas should be accounted for, including assembly lines, manufacturing materials, work benches, conveyor belts, and other equipment that require allocated space.

After you learn about the different warehouse flows and have a good look at your space, you may have a good idea of which design will naturally fit your needs.

If you hope to keep the shipping and receiving areas closed, the U-shaped warehouse flow may fulfill that. If you prefer to keep an in-and-out workflow while minimizing space usage, you may prefer the I-shaped warehouse flow. The L-shaped warehouse flow works if you have a uniquely shaped warehouse.

Whether you pick a popular flow or choose to do things differently, this step is important to sort out before making any major moves in the overall layout.

After determining which flow works best for your needs, it is time to purchase and gather all the necessary equipment to streamline warehouse movements. This includes forklifts, shelving, bins, pallet racks, rolling staircases, picking and packing stations, technology to assist in the process, and other machinery that will help the warehouse run efficiently.

When in doubt, test your proposed plan. Walk through the most favorable traffic flow before implementing and installing equipment into the warehouse layout. Make sure to consider the opinions and concerns of warehouse staff and other employees who actively participate in the workflow.

Despite the benefits of designing a warehouse, there are still challenges. The right warehouse layout should help to mitigate most issues you may encounter along the way. However, preparing to address these in advance is critical.

There are four major challenges you may face as you create your warehouse design and begin implementing the chosen layout.

Once you determine you’re ready to start designing your warehouse, there are a few things you should keep in mind. Use these best practices as checklist items when creating the best layout for your organization.

A warehouse layout should help you improve overall workflow. Before taking advantage of this, make sure the warehouse layout you choose supports your company’s specific objectives. These objectives will help in the design planning process and outline what you hope to achieve with an efficient warehouse layout, like increasing order fulfillment or decreasing shipping and delivery times.

Defining these objectives includes determining warehouse key performance indicators (KPIs), conferring with decision-makers throughout the supply chain, and keeping open communication with those involved with daily warehouse operations.

When in doubt, put a label on it! The key factor to keeping your warehouse layout flowing effectively is to be as organized as possible. Labels can be used in different ways to ensure every item that enters the warehouse is placed exactly where it needs to be. Labeling is also useful for warehouse employees who need to prepare for incoming customer orders.

Guaranteeing the happiness of those who keep your warehouse running is essential. Employees are happy when they know exactly what is expected of them and how they can succeed in their roles. When implementing a new warehouse layout, a training process must be developed so that all warehouse staff understand the flow and what they need to do to ensure smooth movement throughout the floor plan.

Inventory tracking is crucial in determining how much product you have, how much storage capacity you’ll need, and which warehouse layout can accommodate those requirements.

There are several inventory tracking techniques you can use to optimize the way you keep count of the items in your warehouse:

Constant maintenance is necessary to ensure your implemented warehouse layout continues to be successful. Maintenance ensures all the current warehouse processes are effective and still support goals.

Maintenance responsibilities include seeing that all handling equipment is functioning appropriately, taking shipping and receiving trucks to be serviced, keeping all warehousing operations clean, reorganizing inventory and storage when applicable, and conducting quality control checks.

Utilizing a warehouse management system (WMS) helps eliminate human error and keeps processes running efficiently using innovative technologies. A WMS includes software that will help organize physical and virtual warehouses, manage employee productivity, monitor inbound and outbound movements, and coordinate storage and shipping processes. Warehouse management tools allow companies to leverage automation for overseeing daily operations and ensuring data is updated and available at all times.

of companies are already taking automated warehouse systems very seriously and making plans to implement.

Source: G2

A layout is only as good as the metrics it improves. Here are the core warehouse KPIs your layout should directly influence:

| KPI | What is measured | Why it matters |

| Pick rate | Units picked per hour | Gauges speed and efficiency |

| Cycle time | Time from order to ship | Impacts customer satisfaction |

| Dock-to-stock | Time to move goods from receiving to inventory | Affects inventory visibility |

| Order accuracy | % of orders shipped without error | Direct link to returns and CSAT |

| Space utilization | % of used vs. available storage space | Helps avoid under/overutilization |

| Labor utilization | Output per labor hour | Reveals layout/labor alignment issues |

Good layout design isn’t just about efficiency; it’s about keeping your people safe and staying compliant.

Run quarterly warehouse audits to ensure compliance with OSHA, NFPA, and your local building/fire codes.

The type of pallet racking you choose directly affects how efficiently you use vertical and horizontal space.

| Racking type | Best for | Pros | Cons |

| Selective racks | High-SKU environments | Easy access | Lower density |

| Drive-in racks | Large batches, few SKUs | High density | Poor selectivity |

| Push-back racks | LIFO inventory | Space efficient | Limited SKU variety |

| Cantilever racks | Long or awkward items | Flexible sizing | Low density |

Tip: Match racking type to SKU characteristics. Don’t use high-density racks for high-turn, multi-SKU zones.

Include a simple CAD-style diagram in your planning docs to visualize vertical clearance, aisle width, and forklift access.

Have more questions? Find the answers below.

The best warehouse layout for small businesses is a U-shaped layout because it maximizes space, simplifies inventory flow, and supports efficient receiving, storage, and shipping. This layout minimizes travel distance and keeps operations streamlined, making it ideal for limited space and lower inventory volumes.

The main difference between U-shaped, I-shaped, and L-shaped warehouse layouts is their flow and use of space. U-shaped layouts combine receiving and shipping on the same side for efficiency. I-shaped layouts separate inbound and outbound zones. L-shaped layouts place receiving and shipping at adjacent sides for moderate separation.

Warehouse managers should track KPIs such as order accuracy, inventory turnover, picking efficiency, receiving cycle time, and space utilization. These metrics help measure performance, reduce errors, and optimize operations. Tracking these KPIs ensures better inventory control, faster order processing, and improved customer satisfaction.

Warehouse design can improve productivity by optimizing layout flow, reducing travel time, and streamlining picking and packing zones. Clear signage, adequate lighting, and automation also support faster operations. A well-designed warehouse minimizes delays, improves accuracy, and boosts overall throughput.

OSHA requirements for warehouse layout include clear aisle spacing, marked exit routes, safe stacking of materials, and unobstructed emergency exits. Aisles must be at least 3 feet wider than the largest equipment used. Layouts must support fire safety, proper lighting, and access to first aid and safety equipment.

Design a warehouse for automation by creating wide, clear aisles, integrating conveyor systems, and using standardized storage units. Plan for robotics, automated picking, and warehouse management systems (WMS). Ensure layouts support smooth equipment flow, minimal manual handling, and scalability for future tech upgrades.

The best racking systems for maximizing space are pallet flow racks, drive-in racks, and push-back racks. These high-density systems reduce aisle space and increase vertical storage. Pallet flow uses gravity for rotation, drive-in allows deep storage, and push-back offers last-in, first-out access for fast-moving inventory.

Future-proof your warehouse layout by designing for modularity, scalability, and automation. Use flexible racking, allocate space for robotics, and implement a warehouse management system (WMS). Plan for changes in inventory size, order volume, and technology to adapt quickly without major redesigns.

Picking your warehouse layout can feel like a science. It’s all about analyzing your current demands, identifying your future goals, and determining what your warehouse needs to look like to meet them. There is also no limit to what you can create in the design process. Although there are three popular layout flows, how your warehouse ends up organizing movement all comes down to your capabilities and what you are hoping to achieve.

After outlining your objectives and ensuring that all necessary spaces have been considered, you will begin to put your warehouse layout puzzle together, and you’ll be one step closer to streamlining your operations.

Feeling confident about your warehouse layout design? Check out some helpful inventory management techniques to streamline how you manage warehouse organization.

This article was originally published in 2021. It has been updated with new information.

Alexandra Vazquez is a former Senior Content Marketing Specialist at G2. She received her Business Administration degree from Florida International University and is a published playwright. Alexandra's expertise lies in copywriting for the G2 Tea newsletter, interviewing experts in the Industry Insights blog and video series, and leading our internal thought leadership blog series, G2 Voices. In her spare time, she enjoys collecting board games, playing karaoke, and watching trashy reality TV.

What is it that makes renewing a passport so daunting?

by Meghan Treptow

by Meghan Treptow

Sometimes you just have to get away. Far away.

by Meghan Treptow

by Meghan Treptow

During its nearly 30-year history, Adobe Photoshop has become the byword for image editing...

by Meghan Treptow

by Meghan Treptow

What is it that makes renewing a passport so daunting?

by Meghan Treptow

by Meghan Treptow

Sometimes you just have to get away. Far away.

by Meghan Treptow

by Meghan Treptow