August 5, 2020

by Matthew Wright / August 5, 2020

by Matthew Wright / August 5, 2020

The most overlooked part of manufacturing is the most important when it comes to supply chain modernization.

It’s impossible to overstate the importance of supply chain management. In fact, many organizations from consumer goods to life sciences and food and beverage now have Chief Supply Chain Officers. This is a reflection of the growing complexity and strategic importance of the function.

But why have supply chains gotten more complex? After all, we arguably live in the most digital, connected era – surely companies must have all the right tools in place?

It turns out they don’t, and most operators from Fortune 500 to challenger brands would tell you the same. And the biggest gap is probably the most shocking. Most companies don’t actually know everything about what they make. They don’t have all of the data or instructions, commonly referred to as specifications, that are required by parties across the supply chain.

But this is starting to change with the emergence of specification management software. Companies are realizing that specifications are the digital thread that connects supply chain networks. In this article, we’ll define specification management software, discuss the broader trends that led to its rise, and how the software fits into the broad supply chain technology ecosystem.

Everything you see is built from specifications. Your car, clothing, food, and appliances are all attached to a series of data points and technical documentation that define how something is made or how it should operate.

Up until now, professionals have struggled with effectively managing specification data. From legacy systems, to emails, or even simply pen and paper, no method had been specifically designed to store and use specification data, which can run from hundreds of data points to thousands for each product or component part.

Specification management software houses the granular information it takes to make a product – from ideation to manufacturing – and enables companies to easily share that data externally with suppliers, manufacturers, or retailers.

Specifications can be raw materials, formulas, ingredients, bill of materials, certificates of analysis, machinery and so on. This might seem broad, but it’s true. And it’s not just these individual data points that matters. The magic is being able to understand how specifications relate to one another.

A critical element of specification management is the ability to link specifications together in a way that enables supply chain intelligence.

For example, when you link packaging specifications to finished goods, you can easily understand what products are impacted if you want to update a design. Or maybe a critical ingredient for your product is no longer available. You can quickly see which products are impacted or maybe you look at a similar product to identify an alternative. Worst case scenario, you’re experiencing a product recall and can quickly identify if the root cause will impact other parts of your company.

None of this analysis is possible without proper specification management.

Now that we’ve established what specification management software is, why is it only recently coming into existence? We only need to look as far as current consumer trends for that answer.

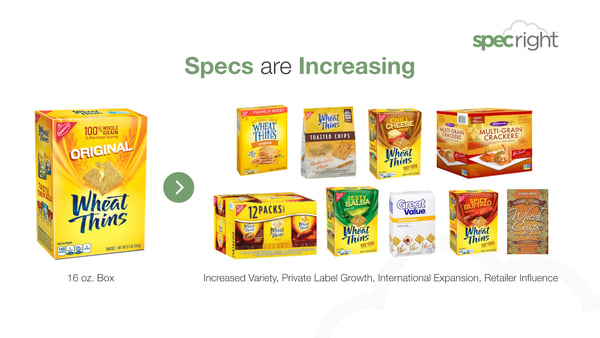

The first explanation is simple: the number of specifications are increasing. Customers used to go to a grocery store and see one version of a product. Today, we might see a box of original Wheat Thins, but then continue down the aisle and see multigrain Wheat Thins, zesty salsa Wheat Thins, snack sized Wheat Thins, and so forth. Formally called SKU proliferation, the industry recognizes that the consumer is king and to keep up with constantly changing tastes and preferences, extended product lines exponentially to maintain markets reached.

The second trend contributing to the need for specification management is globalization. In this day and age, companies are able to reach markets all over the world. And while businesses can offer the same product in every country, more often than not, each country has different product lines available to accommodate individual markets.

Unfortunately, due to the systems on the market for managing global operations, companies often find themselves without any visibility into what other locations are doing, causing poor supplier management, slower product development cycles, and procurement inefficiencies.

The industry only keeps exacerbating the need for specification management. Globalization and SKU proliferation are intensified by other emerging trends, such as the push for sustainability, localized operations, and the increase of private retail brands. As more and more factors increase the complexity of the supply chain, we need software built to meet the needs of specification management specifically.

The key benefit of specification management is visibility. Legacy systems are notorious for being inefficient and outdated, resulting in the inability of supply chain members to see what’s actually going on in other facilities.

Lack of visibility often results in product variation, regulatory and compliance issues, recalls, and ultimately, wasted time and resources. Increasing supply chain visibility enables more robust and agile operations, as well as opens the door to other opportunities such as sustainability and supplier collaboration. Let’s dive into the key business outcomes that specification management enables.

Previously, professionals would use SKU proliferation to account for ever-changing demands, market shifts, and globalization. If you offer more products, you get more customers, right?

Unfortunately it’s not that simple. The average grocery store in 1990 carried about 7,000 SKUs, while the modern day grocery store carries upwards of 40,000 SKUs. Although the number of SKUs soared, the way they were managed remained the same. Despite there being more products available, under performing products were slipping through the cracks, going unnoticed, and eating away at profit margins.

Without specification management tools built to handle SKU proliferation, companies have struggled to leverage offerings while increasing profits. SKU proliferation caused a tectonic shift in the industry, leading executives to search for other ways to continue to grow while keeping costs down.

Now, companies are utilizing SKU rationalization, which is a method that reduces the number of SKUs or underlying component parts based on lack of performance, duplication, or obsolete product statuses. SKU proliferation often occurs by accident and is usually the result of poor specification management.

After all, if engineers can’t easily see what’s already been made, most default to creating something new. Repercussions of this include higher inventory and holding costs, which can exhaust as much as 40 percent of a product’s profits annually.

Specification management enables companies to see which of their products need to be pulled from the product line and which should be invested in further. For example, Unilever had 1,600 brands in 1999, with sales occurring in 150 different countries. They found that a core 400 brands accounted for over 90% of their profits and the other 1,200 were either running losses or making minimal profit. By shedding under performing SKUs, Unilever freed up time and resources to leverage the potential of their main products.

Supply chains have increased in complexity and no industry is immune. Manufacturing, food and beverage, beauty and cosmetics, consumer packaged goods, and packaging supply chains are more disparate than ever.

Before specification management, it wasn't easy to analyze the effects your operations had on your supply chain. Information needed to run actionable reports was heavily siloed and not always up to date. Supply chain blindness makes it difficult to make quick, data-backed decisions that maximize benefits for all stakeholders.

Specification management software allows companies to digitize, map, and operationalize their supply chain, creating a single source of information for how products are made. By tying specs to critical components of the supply chain (such as suppliers, warehouses, and manufacturers), companies obtain a granular view of supply chain operations, helping professionals understand where bottlenecks and waste are occurring.

Suppliers and vendors aren’t just order fulfillers, but valued supply chain partners who are vital to a brand’s success. All players in the supply chain must recognize that fulfillment takes careful planning and execution to produce a successful outcome.

With specification management, brands can easily provide current data from a single platform. This means no more duplicating specs across suppliers and a better understanding of your brand’s needs, resulting in more timely and efficient execution and more accurate bids. With everyone in the loop, you can instantly gain visibility into production, supplier performance metrics, and assurance that your products are being made right.

Detailed technical documentation is vital for working through the new product development process. Specification management software helps companies kickstart ideation by utilizing current specification data or bill of materials that can be cloned, adapted, or combined for use in a new product.

Most of the time, the data needed to create a new product already exists. Instead of trying to reinvent the wheel every time you create a new product or component, maximize the potential of your current data and increase productivity and innovation.

Once you have a product idea, share specs with your supply chain to speed up prototype turnaround. Quickly build out BOMs, streamline project management, and forecast cost to determine profitability of your new product from the start, all with specification management software.

Sustainability is no longer just a buzzword, it’s changing the way decisions are made and businesses are run. Consumers and industry professionals are demanding more accurate reporting, meaning sustainability must start with the DNA level of your data: specifications.

Step one in a corporate sustainability plan is to digitize and centralize all specifications, down to details such as recyclability of materials and information about the supply chain environment. Housing this information in specification management software helps to facilitate stakeholder engagement. Since sustainability requires involvement from nearly every department, centralizing information helps stakeholders collaborate and understand what data to provide.

After putting all necessary data in a specification management system, you can begin to convert sustainability goals into measurable actions. Accelerate Life Cycle Assessments, rationalize SKUs, pinpoint opportunities for material changes or consolidation. Let specification management help your company go from being reactive to proactive when implementing sustainable practices.

Software deployment is often characterized by arduous tasks, long meetings, and excessive data entry. In fact, most product people I talk to are once burned, twice shy when implementing a new system. This is because companies have typically invested in ERP systems that took years to implement and were extremely ridgid.

Specification management systems are designed to be more flexible than ERPs and easier to implement. Most companies chose to onboard data by department or by product line to streamline onboarding and get users accessing the platform to more quickly realize value. Another best practice is to provide logins across departments and suppliers so all stakeholders are accessing live information and any changes are captured in history.

Most of the time, companies have systems in place to manage parts of their data, such as purchasing or inventory. Specification management systems were built to exist symbiotically with enterprise systems to push and pull data that should be shared. For example, it’s beneficial to integrate purchase orders from ERPs into specification management systems to better understand what you’re buying.

You can also integrate with food labeling systems to auto generate nutrition panels, inventory management systems, and business intelligence tools.

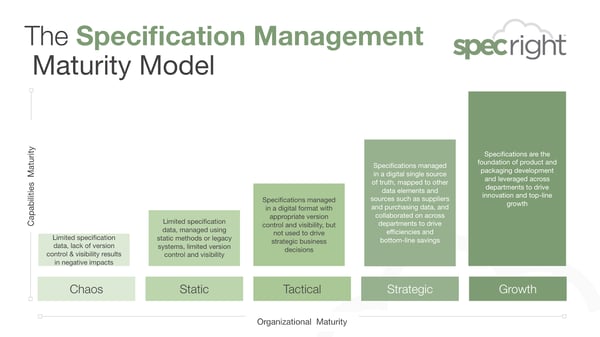

Companies have an abundance of data, but are merely scratching the surface when it comes to using that data to make better decisions. Before reaching the growth stage of the specification management journey, businesses typically go through four levels of maturity.

The first stage is characterized by chaos. This stage is preliminary to having any consistent method of managing specs and results in major time expenditures searching for data. At this maturity level, information is extremely siloed and tribal knowledge is prevalent.

The second stage, or the static stage, is where specifications are managed in static methods, including spreadsheets, emails, or pen and paper. There’s limited version control and obvious negative impacts such as waste, over budget operations, and projects that are behind schedule. This stage is where companies begin to search for a better solution.

The third stage where the foundation for effective specification management is laid. Specifications are housed digitally, with version control and cross-departmental visibility. The data exists in a useful format, but has yet to be used to drive business strategy and decision making.

The fourth stage is when companies begin using specification data to take a strategic rather than reactive approach to managing their supply chain. Specifications are mapped to other data points such as suppliers, BOMs, and purchasing data to analyze and report on supply chain activities. Armed with this information, companies can drive efficiencies and cut costs.

The final stage of maturity is growth, where specifications are truly used as the company’s best source of big data. In this stage, product development is accelerated, more profitable new products are launched, and true supply chain visibility is established.

One topic we haven’t covered is the impact specification management has on people. The best part of my job is hearing packaging engineers or product development professionals tell me about how they love their jobs again.

With specification management, supply chain professionals are no longer spending time chasing data, they’re doing what they were trained and love to do – and that’s making amazing things. As the world continues to demand more of products, we can all agree that giving these professionals the right tools to do their job is a benefit to us all.

Find the best specification management software for your business needs – only on G2.

Matthew Wright is the Founder and CEO of Specright, a purpose-built platform for specification management. He spent 25 years in packaging, holding leadership positions at International Paper, Temple Inland, and rightPAQ – a company he co-founded. He sits on the Packaging Advisory Board at Cal-Poly.

If a product is being sold but there’s no one around to buy it, does it really exist?

by Alexandra Vazquez

by Alexandra Vazquez

With the rapid expansion of technology making communication easier than ever, new and exciting...

by Piper Thomson

by Piper Thomson

If a product is being sold but there’s no one around to buy it, does it really exist?

by Alexandra Vazquez

by Alexandra Vazquez

With the rapid expansion of technology making communication easier than ever, new and exciting...

by Piper Thomson

by Piper Thomson