November 21, 2025

by Izabelle Hundrev / November 21, 2025

by Izabelle Hundrev / November 21, 2025

The more products you carry, the harder it gets to answer simple questions like: What’s selling? What needs restocking? Where’s that item stored?

Inventory only runs as smoothly as the systems behind it, and that starts with how products are named, tracked, and stored. For growing retail and supply chain operations, SKU numbers and warehouse management software work hand in hand to bring order to complexity.

An SKU number is a store-specific code used to identify and manage individual products. It stands for stock keeping unit and helps retailers track inventory, sales, and product variations such as size or color. Unlike barcodes, SKU numbers are created internally and customized by each business.

Your SKU system is the backbone of product distribution. Without it, tracking inventory, forecasting demand, and scaling operations becomes a guessing game.

In this article, we’ll break down what SKU numbers are, how they differ from UPCs, and how to build a system that supports accuracy and growth.

The purpose of a SKU number is to uniquely define and distinguish each product variant in your inventory using a consistent, internal code that reflects how your business organizes and identifies items.

By encoding product attributes like size, color, brand, or category, SKUs serve as a reference system. They allow you to systematically classify products, differentiate similar items, and maintain clarity across your catalog, especially as it grows.

Without SKUs, products become ambiguous, making them difficult to count, reorder, locate, or describe clearly across teams or tools. With them, every item has a defined place in your catalog, and every action tied to that item, from receiving to shelving to selling, can be tracked with clarity.

In technical systems, SKUs act as primary keys: they link all associated data from pricing and supplier info to stock levels and product metadata. They’re also essential for logic-based operations, such as sorting, filtering, matching, and synchronizing inventory across platforms.

Creating SKU numbers is a mix of logic, consistency, and the right tools. Whether you're building them manually or using software, your SKU format should reflect how your business organizes and sells its products.

You can create SKUs in a simple spreadsheet or use inventory management software that automatically generates and tracks them for you. Some tools also include built-in SKU generators, which allow you to define product attributes and generate codes instantly.

Follow the steps below to create your own SKU number:

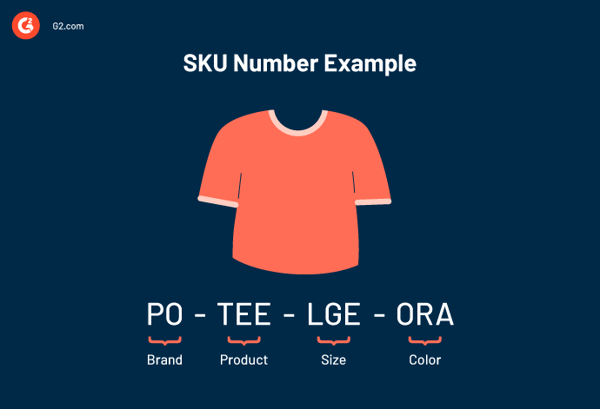

For example, if you sell orange t-shirts, your SKU numbers might be eight-digit. Here, the first two digits represent the brand name (like Nike or Adidas), the next three digits depict the product category (like t-shirt, poncho, sweater), and the next three digits encode the fit (small, medium, or large), followed by color (any color).

You can also organize products based on gender (male/female) or kids' age (0-6, 6-12, and so on).

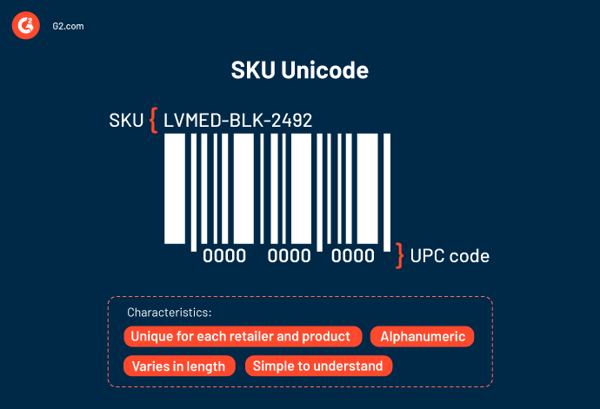

In the image below, you can notice an OMR code that incorporates implicit product information. The SKU number is LVMED-BLK-2492. The standard convention would be brand name (LV), size (MED), BLK(product color black), and 2492 (SKU number).

Guidelines for creating a simple and easy-to-maintain SKU logic:

As you can see, there’s a lot of room for flexibility. What works for the retail shop next door might not work for you, so take a long look at your inventory and develop an SKU naming convention easily understood by you and your employees.

While both SKUs and universal product codes (UPCs) are used to identify products, they serve very different purposes, and they’re created and managed in different ways.-png.png?width=600&height=375&name=Copy%20of%20X%20vs%20Y%20Template%20(42)-png.png)

SKU numbers are unique identifiers assigned to each product, differing by store and product details such as shape, size, and color, to help retailers manage their inventory effectively.

A universal product code is a 12-digit code that is purchased and licensed by all leading manufacturers in North America for the ease of international logistics. It irons out your entire supply chain process and keeps your products consistent and compatible with e-commerce platforms and offline storefronts. It also speeds up the inventory process by standardizing product details and pricing. UPCs are assigned by the Global Standards Organization (GS1). Most large retailers require that a product have a UPC in order to be sold.

While a UPC number stays the same across different product styles and patterns, a SKU number is created after carefully examining a product's manufacturing details.

Below, we have summarized the differences between SKU, UPC, and a barcode.

| Feature | SKU | UPC | Barcode |

| Purpose | Internal inventory tracking | Universal product identification | Fast, machine-readable scanning |

| Created by | Business (custom) | GS1 (licensed) | Auto-generated by systems |

| Format | Alphanumeric (flexible) | 12-digit numeric | Visual (lines or QR) |

| Used by | Retailers, warehouses | Manufacturers, retailers | POS systems, scanners |

| Scope | Business-specific | Globally standardized | Tied to SKU or UPC |

| Format | LVMED-BLK-2492 | 012345678905 | |||| ||| |||| (representing barcode lines) |

A clear SKU system streamlines your entire inventory workflow, from sourcing and storage to sales and customer service. By assigning unique SKUs to each product variant, retailers can:

G2 helps businesses find the best warehouse management tools for simplifying SKU tracking, optimizing inventory workflows, and scaling fulfillment across multiple locations.

Below are the five best warehouse management systems, based on G2’s Winter 2026 Grid® Report:

Even well-intentioned SKU systems can break down if they’re not built with consistency, context, and long-term use in mind. Here are some common SKU mistakes that go beyond naming conventions:

A good SKU system should be simple, scalable, and aligned with your business's operations. Keep these best practices in mind:

Got more questions? We have the answers.

Yes. SKUs are internal, business-defined codes, so two different companies can use the same SKU for completely different products. What matters is that SKUs are unique within your own system.

Most SKUs fall between 8 and 12 alphanumeric characters, but there’s no universal rule. The best length is one that stays readable for humans, reliable for systems, and flexible enough for future product growth.

Only if you want unified tracking. Reusing SKUs across stores, warehouses, or sales channels makes it easier to consolidate inventory data and reporting. If different locations manage inventory differently, you can layer location codes into the SKU or manage location logic inside your WMS or point-of-sale system instead.

Yes. Consistency is what gives SKUs long-term value. Even if different product categories need different attributes, the overall structure and naming logic should stay stable so teams can interpret SKUs quickly and systems can sort them cleanly.

Use SKUs for internal product tracking and inventory logic. Use UPCs when selling through external channels that require universal identification.

A good rule of thumb is quarterly or biannual audits, depending on how fast your catalog changes. Audits help catch duplicates, inconsistent formats, outdated codes, and product lines that no longer match your SKU logic.

A SKU might look like just a random code, but it’s one of the most useful tools for keeping your inventory in order. With the right system, SKUs help you track what’s selling, where each product is stored, and when it’s time to restock. They make it easier for your team to find items, avoid mistakes, and keep customers happy with fast, accurate service.

If you’re ready to upgrade your inventory management, browse our curated list of top inventory control software to find tools suited for your business.

This article was originally published in 2019. It has been updated with new information.

Izabelle is a Partner Marketing Specialist at InStride and a former content specialist at G2. Outside of work, she is passionate about all things pop culture, food, and travel. (she/her/hers)

Managing inventory can be daunting. While I don’t run a warehouse or oversee stock levels...

.png) by Tanuja Bahirat

by Tanuja Bahirat

Do you trust AI? Not just to autocomplete your sentence, but to make decisions that affect...

by Soundarya Jayaraman

by Soundarya Jayaraman

Social media is an integral part of most people’s lives. And as we all know, anything posted...

by Rebecca Reynoso

by Rebecca Reynoso

Managing inventory can be daunting. While I don’t run a warehouse or oversee stock levels...

.png) by Tanuja Bahirat

by Tanuja Bahirat

Do you trust AI? Not just to autocomplete your sentence, but to make decisions that affect...

by Soundarya Jayaraman

by Soundarya Jayaraman