If there is one thing that we all strive for, it’s balance.

Balancing our careers with our personal lives, spending time with friends and family, and munching on a carrot for every cookie we eat. All in all, we use these balancing strategies to learn, grow, and improve.

Businesses shoot for the exact same thing. However, instead of work-life balance, time management, or a diet plan, they like to call it economies of scale.

|

Want to skip ahead to read more about certain aspects of economies of scale? Use these jump links to focus on a particular area:

|

What are economies of scale?

Economies of scale are the cost benefits gained by companies when production becomes more efficient. A business achieves economies of scale when they boost production while also lowering costs.

Essentially, economies of scale is a fancy phrase meaning that a business sees some positive changes when their production becomes more economical. Reaching the perfect balance between production and cost brings about certain benefits.

How do you calculate economies of scale?

To calculate economies of scale, divide the percentage change in cost with the percentage change in output. If the result is less than one, that means that economies of scale exists.

As a company grows and produces more, they have a better chance of reducing costs. When the economy of scale is realized by a particular business, they start to reap certain benefits.

Sounds pretty simple, right? Increase production and lower costs. Like a lot of business goals, it is easier said than done. Hitting that sweet spot takes time and effort, and a lot of factors play into it.

Effects of economies of scale

Economies of scale most directly affect production costs. When economies of scale occurs, businesses can experience two positive outcomes:

- A reduced per unit fixed cost. When a company starts to produce more, the fixed cost of production is spread across more units, making it smaller.

- A reduced per unit variable cost. The expanded scale of production also makes it more efficient, avoiding additional variable costs.

|

Tip: A big part of improving production is improving the product itself. Take a look at some product management software to help your team collect ideas and eventually create an improved final product.

|

Diseconomies of scale

So, let’s say a business has successfully increased output. That’s great, right?!

Well, not all of the time, unfortunately.

Sometimes, when a business expands outputs, it can come with increased costs, as opposed to its hoped-for opposite. This is called diseconomies of scale. They can occur as a result of both internal and external factors, and there are three main types.

Technical diseconomies of scale include physical limits to production. The biggest contributor to this is overcrowding. When a company grows too quickly, and they think they can achieve economies of scale simply by growing, the opposite can actually happen.

Organizational economies of scale is directly related to managing a large workforce. As a business grows, certain necessary functions can struggle and come across as unfocused.

External diseconomies of scale are out of control of the organization and include situations where the economy or industry within which a business works is not working in its favor. Some common external economies of scale includes lack of demanded resources, constraints imposed on a business, or a change in the price of inputs.

Types of economies of scale

There are two different types of economies of scale that affect a business: internal and external.

Internal economies of scale

Internal economies of scale are controllable by management because they are happening within the organization. A business achieves internal economies of scale when they have simultaneously increased production and lowered costs.

Typically, internal economies of scale are achieved by larger organizations. They have more experience and knowledge of efficient production practices, the ability to buy in bulk, cheaper access to capital, and highly connected networks. All of those factors contribute to achieving internal economies of scale.

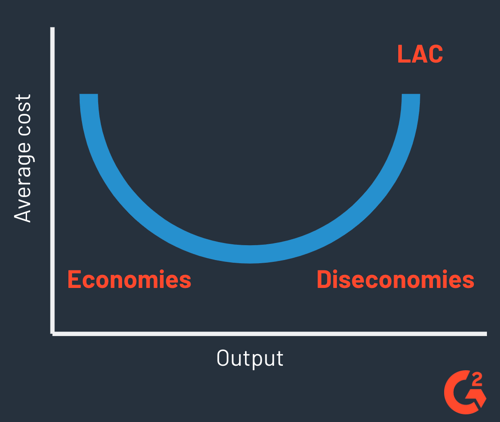

Below is a graphical representation of internal economies of scale.

With internal economies of scale, a business can fall anywhere on the long run average cost (LAC) curve, which is a representation of the concept of savings made by increasing output. However, if the average cost starts to rise, they fall into diseconomies territory.

External economies of scale

External economies of scale occur outside of a business but within the industry it works within. They are achieved when some external factor positively affects an organizations business operations. When external economies of scale occurs, every business within the industry benefits.

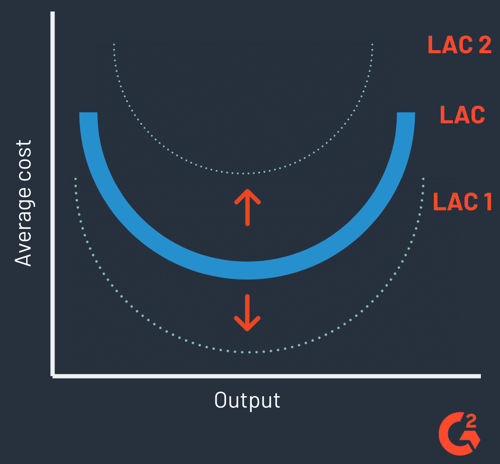

The representation of external economies of scale is a bit different. Take a look at it below.

As opposed to a business falling somewhere on the LAC curve with internal economies of scale, external economies of scale shift the curve completely. When the industry or economy shifts, so does the curve. Businesses are forced to keep up if they want to achieve external economies of scale.

Sources of economies of scale

A business can’t achieve economies of scale overnight. There are multiple factors that go into efficiently producing goods and services. Let’s take a look at each one.

Lower input costs

This one seems pretty obvious, but when a business has lower input costs, economies of scale can occur. This is usually done by taking advantage of volume discounts by buying products in bulk.

Costly inputs

This doesn’t mean that businesses want to pay more for inputs - it means they want to get their money’s worth. Some inputs are going to cost more than others. Research, advertising techniques, and hiring experienced professionals is expensive. However, if the efficiency of these inputs is increased, that can result in lowering the average cost of the product.

Specialized inputs

When a business starts to produce more, they can start to use specialized machinery and labor practices. An example of this would be moving someone from a labor position into something more specialized and replacing them with a piece of equipment that specifically performs the task that a human once did.

Organizational inputs

A business can also better organize its resources to achieve economies of scale. This includes establishing a chain of command and improving production and distribution techniques.

Learning inputs

Overall, practice makes perfect. The more a business learns about what works best for them, takes advantage of available resources, and adjusts processes when necessary, the more efficient they will be. This includes applying knowledge, adapting, and changing.

The beauty of balance

Economies of scale is essentially growing and becoming more efficient at the same time. Expansion is usually seen as a good thing, but if one aspect of a business can’t keep up, everything else falls apart with it. Before expanding, businesses must first understand what factors will affect them the most throughout the process.

There are plenty of ways for a business to grow, and a good place to start is the people within it. Check out our resource on growth opportunities that will make your employees smile.

by Kamaljeet Kalsi

by Kamaljeet Kalsi

by Shruti Nair

by Shruti Nair

by Grace Pinegar

by Grace Pinegar