On a scorching summer day, the office AC broke down. The maintenance team scrambled to find the issue, but without a proper tracking system, they had no record of past repairs or replaced parts.

As a result, it took hours to fix, and in the meantime, productivity plummeted, and everyone struggled in the heat. That got me thinking—how do maintenance teams, facility managers, and manufacturers handling far more critical equipment deal with unexpected breakdowns?

That’s when I started exploring best computerized maintenance management system (CMMS) software.

I explored G2 reviews, researched various platforms, and evaluated G2 reviews for different CMMS tools to understand their impact. I found that these systems go beyond simple tracking—they optimize asset performance, reduce downtime, and improve overall efficiency.

If you're searching for the best CMMS software solutions, keep reading. I’m sharing insights from my evaluation experience to help you find the right tool for your needs.

10 best CMMS software: My picks for 2025

- MaintainX: Best for quick work order setup and ample asset management.

for fast implementation, mobile friendly interfaces, and intuitive work order. ($16/user/mo)

- Fiix CMMS: Best for AI-powered maintenance automation and deep analytics

to automate maintenance schedules, optimize asset time, and deliver analytics. ($45/user/mo)

- Limble: Best for customizable workflows with intuitive UI

For customization, tailoring maintenance workflows, checklists and dashboards. ($69/user/mo)

- UpKeep: Best for mobile-first maintenance teams and cloud access

For offline functionality, cloud-based accessibility, and modern UI.($20/user/mo)

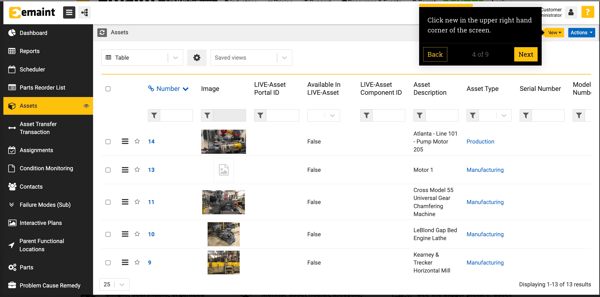

- eMaint CMMS: Best for compliance focused maintenance and scalability

For detailed audit trails, compliance reporting, and asset hierarchy management. ($69/user/mo)

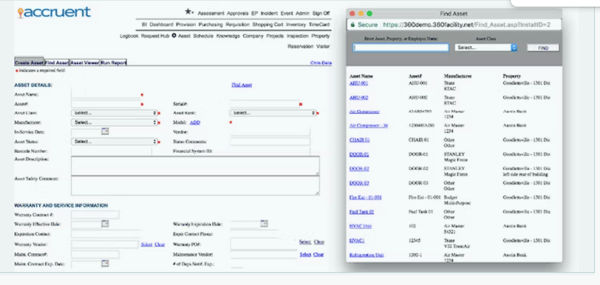

- Accruent Maintenance Connection: Best for enterprise grade asset lifecycle

For large enterprises needing advanced tools for complex asset lifecycles. ($1325/user/year)

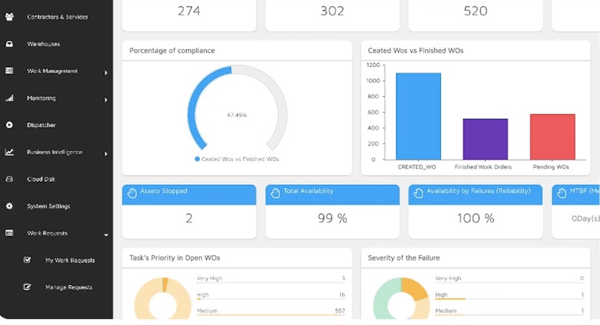

- Fracttal One: Best for predictive maintenance and IoT integration

To drive predictive maintenance insights and help reduce downtime.

(available on request)

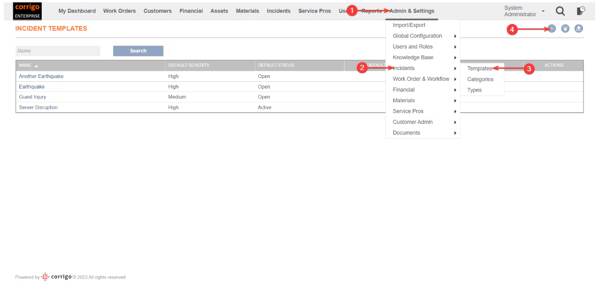

- Corrigo: Best for vendor co-ordination and facilities management

To drive predictive insights, reduce downtime and extend asset lifespan. (available on request)

- eWorkOrders CMMS: Best for preventive maintenance scheduling

for strong preventive maintenance capabilities (available on request)

- Click Maint CMMS: Best for simple maintenance scheduling and cost tracking For simplified maintenance planning and scheduling with affordability. ($35/user/mo)

* These CMMS tools are top-rated in their category, according to G2 Grid Reports. I’ve also added their monthly pricing to make comparisons easier for you.

My top 10 best CMMS software recommendations for 2025

Best CMMS software is designed to help businesses efficiently track, maintain, and optimize their assets. While exploring these tools, I saw how they simplify maintenance management, reduce unexpected downtime, and improve overall equipment reliability.

According to Grand View Research, the global computerized maintenance management system market size was estimated at USD 1.29 billion in 2024 and is projected to reach USD 2.41 billion by 2030, growing at a CAGR of 11.1% from 2025 to 2030.

Features like automated maintenance scheduling, real-time work order tracking, and predictive insights help businesses avoid equipment failures instead of constantly reacting to them. I could see how the best CMMS software did all of that and more.

How did I find and evaluate the best CMMS software?

I evaluated reviews for the best CMMS software extensively to understand how they manage and track maintenance tasks, automate work orders, and optimize asset performance.

I used AI to analyze user feedback and reviews on G2 and G2’s Grid Reports to gain further insights into each tool’s features, ease of use, and overall value. The screenshots featured in this article may be a mix of those captured during evaluations and ones obtained from the vendor’s G2 page.

By combining evaluations from expert feedback and user reviews, I’ve compiled a list of the best CMMS software to help you select the right one for your maintenance operations.

What makes CMMS software worth it: My opinion

When evaluating the best CMMS software, I focus on several key features to determine its effectiveness for IT and maintenance teams:

- Asset tracking and management: A CMMS should function as a centralized asset database, providing real-time visibility into equipment, machinery, and facilities. I evaluate how easily users can input asset data manually or via bulk import (CSV, API integration). Searchability is crucial, so I evaluated whether assets can be found using filters like asset type, location, serial number, or maintenance status. I also check for barcode and RFID scanning capabilities, which speed up asset identification. A well-designed CMMS should allow users to attach technical documents (PDFs, images, CAD drawings), warranty details, and IoT sensor data to each asset record for comprehensive tracking.

- Preventive maintenance scheduling: Automation in preventive maintenance ensures that equipment gets serviced before failures occur. I assess whether the CMMS allows scheduling based on time intervals (e.g., every 30 days), usage (e.g., after 500 machine hours), or condition-based triggers (e.g., temperature exceeding 80°C). I also check for built-in workflow automation—can it automatically generate work orders when a maintenance task is due? The best CMMS solutions integrate with IoT-enabled sensors to capture live equipment data and trigger maintenance alerts dynamically.

- Work order management and tracking: Work orders should be easy to create, assign, and update in real-time. I evaluate whether users can generate work orders manually or through automated triggers (e.g., an equipment fault detected by a sensor). A CMMS should support multi-user collaboration, allowing technicians to update job progress, attach images, log used spare parts, and enter detailed issue notes. I also evaluated mobile accessibility—can technicians access work orders from a smartphone or tablet while on-site? Advanced systems support role-based access control (RBAC), ensuring that only authorized personnel can modify critical work orders.

- Inventory and spare parts management: A well-integrated CMMS should track spare parts usage and stock levels, preventing downtime due to missing components. I evaluated whether the software provides real-time inventory updates, automatic reorder notifications, and integration with ERP or procurement systems. A good CMMS should support batch tracking, part serial number identification, and supplier management to streamline procurement. I also check whether it calculates lead times to ensure that essential parts arrive before stock runs out.

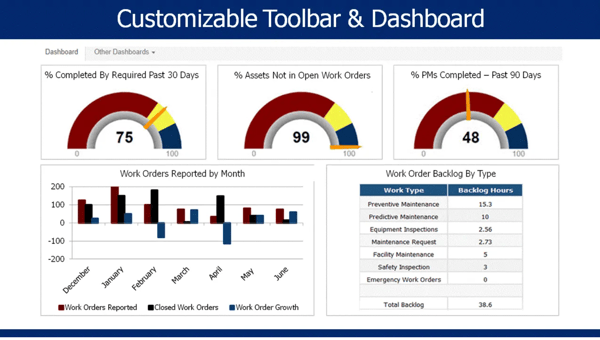

- Data-driven insights and reporting: A CMMS should transform raw maintenance data into actionable insights. I assess reporting tools for key performance indicators (KPIs) like Mean Time Between Failures (MTBF), Mean Time to Repair (MTTR), asset utilization rates, and technician efficiency. The best systems provide customizable dashboards with interactive visualizations (charts, heatmaps) and exportable reports (PDF, Excel, or JSON for API-based integrations). Predictive analytics is another valuable feature—some CMMS tools use AI and ML models to analyze historical data and forecast equipment failures before they happen.

- Compliance and audit readiness: Many industries require strict compliance with safety and maintenance regulations. I check whether the CMMS maintains a digital audit trail of maintenance activities, complete with timestamps, user logs, and digital signatures. Automated compliance tracking should cover industry standards like ISO 55000 (asset management), OSHA (safety regulations), or FDA 21 CFR Part 11 (electronic records). I also verify whether the software allows secure document storage for certifications, warranty records, and safety checklists, ensuring everything is accessible during audits.

By evaluating these technical aspects, I can determine whether a CMMS truly enhances maintenance operations or if it lacks the automation and integration necessary for modern IT and facility management teams.

According to G2's State of Software report, CMMS is one of the 10 most visited traffic categories with the highest traffic with growing investment and adoption.

- Manage various types of assets and equipment across multiple locations

- Track inventory for spare parts and materials needed for maintenance

- Schedule maintenance activities such as inspections, repairs, and upgrades

- Manage resources (human and equipment) and allocate them to maintenance operations

- Deliver reports on asset utilization, maintenance costs, and technician productivity

- Ensure asset compliance with safety and environmental regulations

- Provide a mobile-friendly interface or mobile apps for field service technicians

This data has been pulled from G2 in 2025. Some reviews have been edited for clarity.

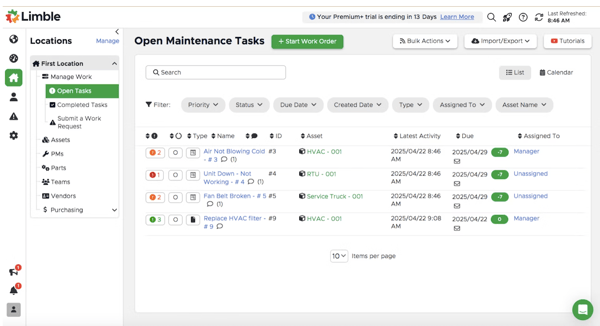

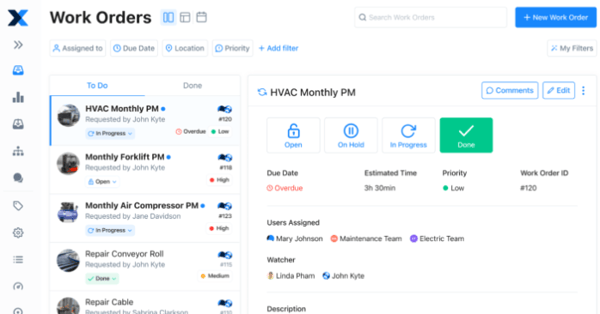

1. MaintainX: Best for quick work order setup and ample asset management

Based on my review of G2 user feedback, MaintainX is a cloud-based Computerized Maintenance Management System (CMMS) designed to streamline maintenance operations for businesses. It helps manage asset performance, work orders, and maintenance tasks, and is particularly appealing to professionals transitioning from spreadsheets.

As a category leader on G2, MaintainX has achieved a perfect satisfaction score of 100, with 96% users likely to recommend it for work order management, preventive maintenance and task templates.

One standout feature that I see getting a lot of praise is automated asset management. From what I’ve seen, G2 users frequently highlight how this functionality seamlessly connects work orders to the respective assets. Unlike outdated Excel-based systems, it automatically logs every maintenance action, creating a clear, searchable history. This helps eliminate the hassle of manual record-keeping and provides users with reliable, organized data.

The procedures feature is also often mentioned positively in G2 reviews. Users seem to appreciate how intuitive and adaptable it is. I’ve noticed that this feature isn't just limited to maintenance tasks but can be used to support various workflows, which makes it more versatile than users initially expect.

Another frequently praised capability is the meter tracking system. Multiple reviewers mention how this feature provides immediate insights into asset performance, allowing users to catch potential issues before they lead to costly breakdowns. Given the importance of preventive maintenance, this tool seems particularly valuable to businesses aiming to reduce unplanned downtime.

From what I’ve gathered in G2 reviews, MaintainX is generally regarded as a robust and flexible tool. Customization options are a major benefit, enabling users to tailor the system to their needs. However, I’ve noticed some concerns about the risk of incorrect data entry when the system is heavily customized. Based on feedback, more control over user permissions could help mitigate this issue by ensuring more accurate modifications.

According to G2 user reviews, MaintainX is praised for its robust asset management and versatile preventive maintenance workflows, though some users mention that onboarding can feel a bit overwhelming. Reviewers note that once teams get past the initial setup, the platform’s intuitive mobile interface makes day-to-day use much easier.

Another area highlighted in G2 feedback is the QR code functionality, which some users feel could be more advanced. While it works for basic scanning, reviewers mention that richer labels with asset details would streamline operations further.

Overall, G2 sentiment reflects MaintainX as a feature-rich and reliable CMMS platform, with its strengths in mobility and workflow flexibility far outweighing these minor usability gaps.

What I like about MaintainX:

- One standout capability, according to users, is MaintainX’s automated asset management, which links work orders to assets automatically, building a searchable history without manual effort.

- I’ve seen G2 reviewers highlight the intuitive procedures feature, noting how it’s easy to adapt beyond maintenance tasks, making the system more versatile than expected.

What G2 users like about MaintainX:

"With MaintainX, we store all our operational procedures, assets, parts, repair records, preventive maintenance plans, and training documents in one place. This has significantly reduced the time our teams spend on communication and tracking repair statuses. It also helps us schedule recurring maintenance and efficiently assign work orders."

- MaintainX Review, John W.

What I dislike about MaintainX:

- While the high level of customization is appreciated, I’ve noticed G2 reviewers point out that it can lead to incorrect data entry if users aren’t careful.

- Based on user feedback, the feature set can feel overwhelming at first, with several reviewers mentioning it took time to get comfortable and that new users might need more onboarding support.

What G2 users dislike about MaintainX:

"The only change I would make to MaintainX is the ability to customize the specific permissions of each full user in the system. "

- MaintainX Review, Joseph M.

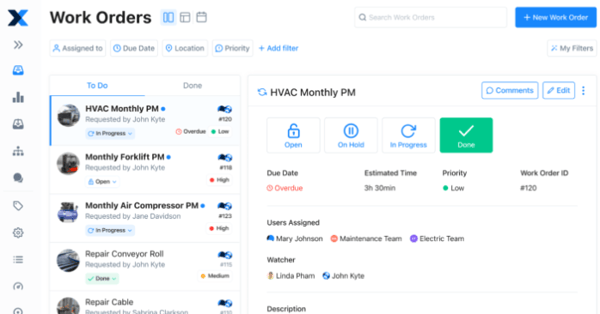

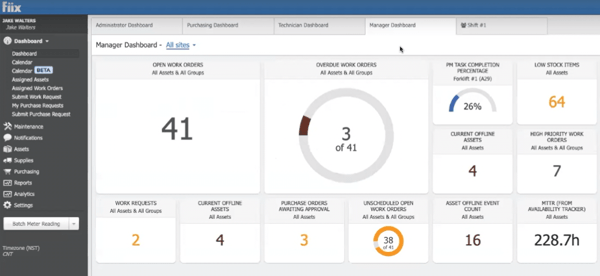

2. Fiix CMMS: Best for AI-powered maintenance and deep analytics

Based on my review of G2 user feedback, Fiix CMMS is a cloud-based tool praised for its accessibility, scalability, and cost-effectiveness. Users appreciate its reduced IT requirements, automatic updates, and the ability to seamlessly analyze maintenance data through artificial intelligence.

Based on 375 user reviews, Fiix has achieved a customer satisfaction score of 80, with 93% G2 users willing to recommend it to others in the overall business segment.

One standout feature that I’ve noticed getting a lot of praise is the system’s ease of implementation. G2 reviewers commonly mention how smoothly the transition from paper-based systems went, and how intuitive the training process was, allowing users to quickly get everything up and running without complications.

A consistent theme in G2 reviews that I’ve noticed is Fiix’s data analytics capabilities. Many users highlight how easy it is to store and analyze historical maintenance data, identifying trends and tracking maintenance indicators in ways that are more seamless compared to other systems. This data-driven approach to maintenance planning is highly valued by users, particularly those looking to optimize their operations.

One feature that stands out in reviews is Fiix’s connectivity, particularly its ability to integrate with programmable logic controllers (PLC) for real-time data collection and automated machine responses. G2 users frequently highlight the system’s integration with integrated plant systems (IPS), centralizing operations and improving overall efficiency. Additionally, the predictive maintenance tools and vibration analysis integration are frequently praised for their ability to detect mechanical issues early and anticipate equipment failures, which are seen as incredibly valuable tools for maintenance teams.

According to G2 user reviews, Fiix CMMS is highly regarded for its AI-powered scheduling and analytics, though some users mention that scheduling flexibility could be improved. While the platform provides a solid foundation for managing work orders, reviewers note that teams with dynamic maintenance needs sometimes wish for more customization.

Another theme in G2 feedback relates to the mobile experience. The app is valued for enabling teams to stay productive on the go, but a few users point out minor inconsistencies between iOS and Android versions.

Overall, G2 sentiment reflects Fiix CMMS as a powerful and analytics-driven maintenance platform, with strengths in automation and mobile accessibility outweighing these usability gaps.

What I like about Fiix CMMS:

- I’ve read G2 reviews highlighting that implementing Fiix CMMS was surprisingly smooth, with users noting a quick transition from paper-based systems and intuitive training that got them up and running fast.

- One feature that gets a lot of praise is the historical data record, which many users found helpful for tracking maintenance trends and using analytics tools to make data-driven decisions.

What G2 users like about Fiix CMMS:

"Fiix is an easy-to-use and intuitive tool for managing projects and tasks within companies. It offers robust reporting and data analysis features, making it a great software solution. Additionally, Fiix provides helpful instructions to assist new users in navigating the application. It is a user-friendly tool for various industries, and one of its biggest advantages is its excellent customer support."

- Fiix CMMS Review, Weronika R.

What I dislike about Fiix CMMS:

- I’ve noticed G2 users often highlight the centralized scheduling as a helpful part of the work order management system, though some feel it's not flexible enough for teams with evolving maintenance needs.

- Based on G2 reviews, there’s noticeable dissatisfaction around the mobile app experience, especially due to inconsistent features between Android and iOS versions, which can impact users relying on mobile access.

What G2 users dislike about Fiix CMMS:

"The system lacks an advanced option for creating scheduled maintenance work orders, similar to what is available in the SAP Materials Management (MM) module. It allows duplicate inspection orders without an intelligent check to prevent them. The app does not fully meet expectations, as the Android and Apple versions differ significantly. Some features are not translated into the selected language, leading to information being displayed in English. Additionally, there is no support for the Brazilian currency (reais). The system also does not allow estimated and execution times to be divided into minutes, making it difficult to convert fractional hours accurately."

- Fiix CMMS Review, Guilherme C.

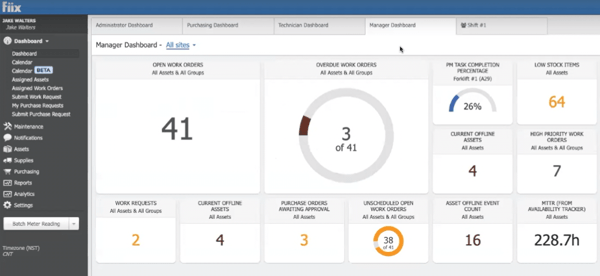

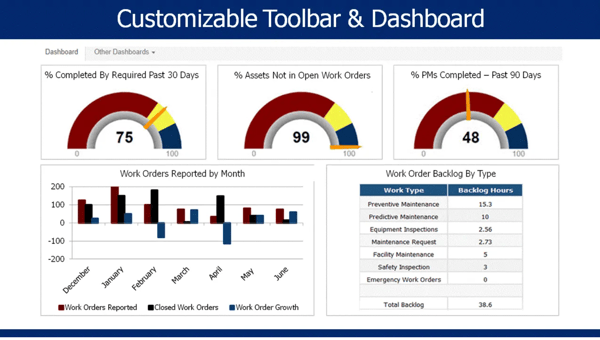

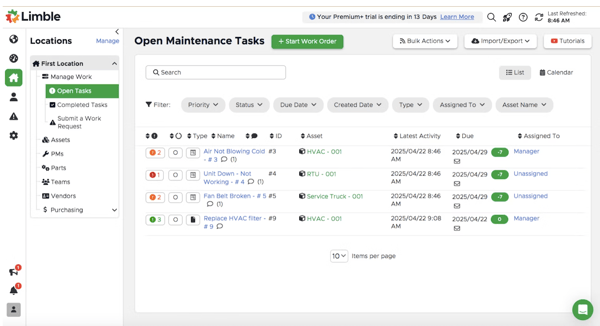

3. Limble: Best for customizable workflows with intuitive UI

Based on my review of G2 user feedback, Limble is a cloud-based CMMS that is frequently praised for its customizability, making it highly adaptable for industries like manufacturing, healthcare, and facilities management.

Based on 472 verified G2 reviews, Limble has recieved a customer satisfaction score of 93, with 97% users willing to recommend Limble to others for predictive maintenance, standard operating procedures and work order management.

A common theme in G2 reviews is the system’s flexibility, allowing users to configure custom fields and refine how maintenance tasks are tracked to fit their specific needs. This adaptability is particularly appreciated by teams looking to seamlessly integrate the system into their existing workflows without requiring major adjustments.

The user interface is another feature that receives a lot of positive attention from G2 reviewers. It's described as clean, intuitive, and easy to navigate, which is especially beneficial for those new to CMMS software. From what I’ve seen, users appreciate how simple the setup process is, ensuring a smooth transition and minimizing complications when getting started.

Another standout feature, according to G2 reviews, is the dashboard, which updates every 5 minutes. Users frequently mention how customizable the dashboard is, allowing them to monitor key metrics in real-time and tailor the data to their preferences. Many users find this valuable for tracking performance and gaining insights at a glance, especially in high-pressure environments where quick access to information is crucial.

According to G2 user reviews, Limble stands out for its customization and intuitive interface, though setting up dashboard widgets can feel overwhelming. While the feature is powerful, some users note that the many technical options make it harder to fine-tune data displays without extra effort.

Another area mentioned in G2 feedback is reporting. Users appreciate Limble’s flexibility, but some find extracting detailed reports tricky and often export data to Excel for deeper analysis, adding an extra step to the process.

Overall, G2 sentiment shows that despite these refinements being requested, Limble remains a trusted CMMS for teams seeking customizable workflows and a user-friendly platform.

What I like about Limble:

- A consistent theme in G2 reviews that I’ve noticed is how customizable Limble is—users appreciate the ability to create custom fields and adjust task tracking to fit their workflows.

- I’ve come across many reviewers who praise the clean and intuitive interface, noting that even users new to CMMS tools find the setup process simple and the transition smooth.

What G2 users like about Limble:

"Limble is simple, powerful, and gets the team excited. The pricing is comparable to previous software but offers more value for our money, plus a free trial to demonstrate how easy it is to use—something no other company (from the demos I've seen) offers. It's a one-stop place to find all the data we need to do our jobs effectively. After reviewing over 12 different CMMS programs, Limble checked all the right boxes, and our team is thrilled to use it every day. Another great thing is the support—Limble has truly excelled in customer service, being available day and night with solutions to even the most unique requests, always answering with "Yes!"

- Limble Review, Alex B.

What I dislike about Limble:

- One feature that I see getting a lot of praise is the customizable dashboard widgets, which let users personalize how they view data—though some G2 reviewers mention setup can be a bit challenging.

- I’ve read multiple reviewers mention struggles with reporting features, noting that while the platform is user-friendly overall, pulling detailed reports from specific datasets isn’t always straightforward.

What G2 users dislike about Limble:

"First, there’s no complete audit trail for task workflows, making it hard to attribute work completion to the correct technician, especially when tasks are assigned to multiple people. Second, metrics like downtime and Mean Time to Repair (MTTR) are only logged once tasks are closed, but some tasks take weeks or months to close, making the data outdated. It would be great if downtime on open tasks could be tracked automatically. Lastly, there’s no good scheduling module, and it’s challenging to manage task scheduling without changing fixed due dates or relying on manual inputs in Excel."

- Limble Review, Verified User in Pharmaceuticals.

Explore inventory control tools that can provide real-time insights into the performance of your asset management processes.

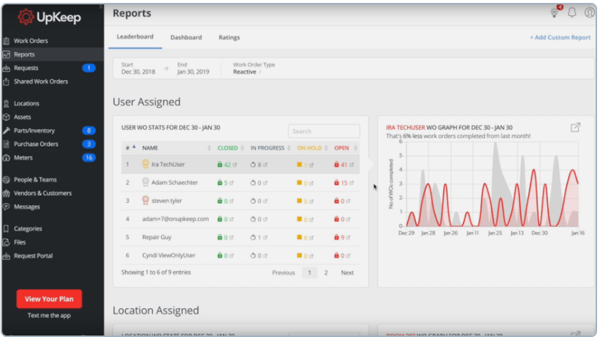

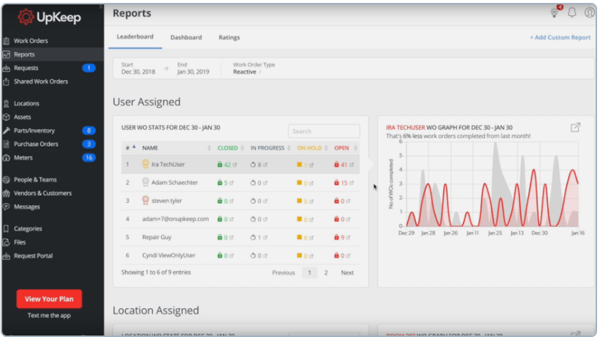

4. UpKeep: Best for mobile-first maintenance teams and cloud access

Based on my review of G2 user feedback, UpKeep is a highly regarded mobile-first, fully featured CMMS designed to enhance maintenance management. A consistently praised feature is its intuitive design, which allows both technicians and requesters to be onboarded quickly.

Based on 952 verified G2 reviews, Upkeep has recieved a decent satisfaction score of 81, with 89% users willing to recommend it to others with small, mid and enterprise sized businesses.

G2 users frequently highlight how the system’s simplicity and ease of navigation enable new users to rapidly learn how to create and manage work orders without feeling overwhelmed. This user-friendly interface appears to be one of the standout features for many.

Adoption metrics are another aspect that receives positive feedback from G2 reviewers. The high customizability of this feature allows users to track how well teams are adopting the system and make adjustments as needed. According to feedback, this flexibility is especially appreciated by users who want to monitor progress and improve system engagement within their teams.

Another feature that stands out in reviews is seamless scheduling for both preventive and reactive maintenance. G2 users appreciate how easily they can assign, track, and adjust maintenance tasks, ensuring that no work orders are missed. Reviewers often mention how this feature contributes to smoother operations, especially when tasks can be built and scheduled simultaneously, helping technicians who are new to CMMS software feel more comfortable with the system.

Real-time work order tracking and mobile accessibility are also frequently mentioned in positive reviews. Users enjoy the ability to check work order statuses, update tasks, and communicate with teams on the go. This feature significantly improves maintenance efficiency, and the centralized data storage enhances collaboration by ensuring that all team members have access to the most up-to-date information, reducing miscommunication and delays.

According to G2 user reviews, UpKeep is appreciated for its mobile-first design and customizable schedules, though bulk importing and exporting work orders can take more steps than expected. Reviewers note that while preventive maintenance is supported, streamlining bulk actions would improve efficiency.

Another theme in G2 feedback is inventory integration. Users value the asset management tools, but some point out that linking work orders directly to stock or automating updates on purchase orders requires more manual effort than they’d like.

Overall, G2 sentiment reflects UpKeep as a reliable and user-friendly CMMS, with its strengths in mobility and asset tracking continuing to outweigh these operational gaps.

What I like about UpKeep:

- I’ve seen many G2 reviewers highlight UpKeep’s intuitive design as a major advantage, making it easy for both technicians and requesters to onboard and manage work orders without much hassle.

- A commonly appreciated element is the adoption metrics feature—from what I’ve read, users value the ability to track system usage and make custom adjustments to boost adoption across teams.

What G2 users like about UpKeep:

"From my perspective in a training role, Diego at Upkeep gave us all the support we needed to get up and running. He took the time to work with various stakeholders, ensuring a proper introduction to the system and a clear understanding. He even joined an employee training call to answer any questions I couldn’t handle. The feedback has been positive—users appreciate how easy the app is to use and how it helps them stay organized, preventing them from losing track. I truly appreciated this level of support for a new system!"

- UpKeep Review, Glenda R.

What I dislike about UpKeep:

- I’ve read multiple G2 reviews pointing out that bulk importing and exporting PM work orders involves extra steps, which can slow down the process and reduce efficiency.

- From what I’ve seen, users express frustration with the inventory management integration, as it doesn’t automatically link work orders to assets or update inventory upon receiving items, requiring more manual work.

What G2 users dislike about UpKeep:

"A few areas for improvement include the PM process for exporting and importing large numbers of Preventive Maintenance tasks, which could be more efficient. Updates should be tested with customer support before being released to customers. More consideration needs to be given to the types of industries using Upkeep, though the platform is improving in this area. Additionally, better customization options for forms are needed."

- UpKeep Review, William C.

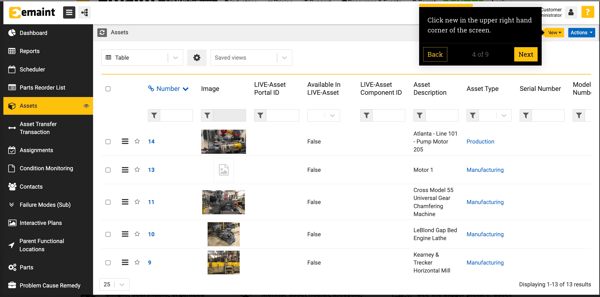

5. eMaint CMMS: Best for compliance-focused maintenance and scalability

Based on my review of G2 user feedback, eMaint CMMS is widely praised for its ability to manage work orders, preventive maintenance, scheduling, asset management, spare parts inventory, and condition monitoring with ease.

Based on 199 verified G2 reviews, eMaint CMMS has achieved a customer satisfaction score of 55, with 90% users willing to recommend it to others in the overall business segment.

One feature that I frequently see getting a lot of praise is its organized system for tracking preventive maintenance. Many users highlight how this functionality is crucial for minimizing machine downtime and ensuring maintenance tasks are scheduled and monitored efficiently, keeping operations on track.

A commonly appreciated element is centralized asset management, which allows users to attach machine user manuals, work instructions, sign-off forms, and parts check-out details directly to each asset. According to G2 reviews, this centralized approach makes the system highly organized, and users seem to really appreciate how everything they need is stored in one place, reducing the hassle of searching across different platforms or physical records.

From what I’ve seen, the integration with inventory tracking and external systems like oil analysis labs is another feature that gets a lot of positive attention. This seamless connection ensures parts are available when needed, which is crucial for avoiding delays and enhancing the efficiency of maintenance operations. G2 reviewers seem to highlight how well this integration works in practice, contributing to smooth operations and reducing the risk of inventory-related issues.

According to G2 user reviews, eMaint CMMS is valued for its scalability and range of maintenance tools, though work order management could be more efficient. Some users mention the inability to close multiple work orders at once, which can be time-consuming when handling backlogs.

Another recurring theme in G2 feedback relates to reporting flexibility. While reports are available, reviewers note that the formats feel limited and that building advanced reports can be challenging without technical knowledge, making it harder for non-technical teams to get detailed insights.

Overall, G2 sentiment reflects eMaint CMMS as a robust and scalable platform, with strengths in maintenance management that outweigh gaps in bulk actions and reporting flexibility.

What I like about eMaint CMMS:

- I frequently see G2 reviewers highlight structured preventive maintenance tracking as a strong point, noting that it helps schedule and monitor tasks efficiently to minimize machine downtime.

- One standout capability, according to users, is the centralized asset management system, which makes it easy to attach manuals, instructions, and part details—streamlining access and reducing the need to toggle between platforms.

What G2 users like about eMaint CMMS:

"eMaint is easy to learn and integrate into your maintenance program. I use it daily to manage assets and create Preventive Maintenance (PM) schedules. It has helped our plant significantly reduce machine downtime by proactively managing PMs. The ability to add machine user manuals, work instructions, sign-off forms, parts check-out, and more for each asset helps keep everything organized in one place. The report-building feature is fantastic for analyzing machine and technician efficiency, and creating custom dashboards with charts and graphs offers a great visual tool. Their support team is always quick to respond and resolve any issues."

- eMaint CMMS Review, Verified User in Manufacturing

What I dislike about eMaint CMMS:

- I’ve come across noticeable dissatisfaction around the lack of a bulk action feature—G2 users mention that not being able to close multiple work orders or delete multiple procedure steps adds time and complexity when managing large workloads.

- Based on my review of G2 feedback, the reporting functionality is another area of concern, with users finding it difficult to customize output formats and noting that advanced reports often require JSON coding knowledge, which not all teams have.

What G2 users dislike about eMaint CMMS:

"The reporting function's output format is limited. X4 could use some format upgrades, though it seems these are being addressed in X5. Additionally, the forms need logic capabilities so that when one item is selected, relevant fields appear. This would help admins guide users more effectively within the system."

- eMaint CMMS Review, Philip A.

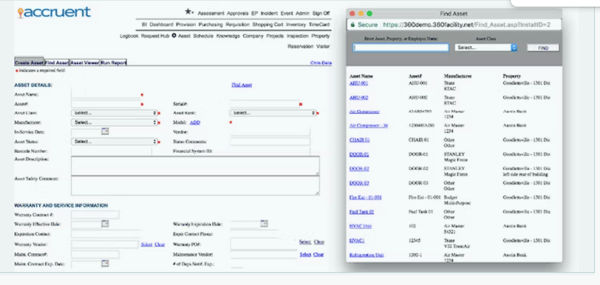

6. Accruent Maintenance Connection: Best for enterprise grade asset lifecycle

Based on my review of G2 user feedback, Accruent Maintenance Connection is praised for its seamless SAP integration for asset parts ordering, which stands out as one of the most appreciated features.

Based on 45 verified G2 reviews, Accruent has a customer satisfaction score of 57, with 89% users willing to recommend it to others in the overall business segment.

Many users on G2 highlight how this integration eliminates the need to manually track parts, making it much easier for maintenance teams to manage inventory without delays. This feature is especially beneficial for businesses already using SAP for procurement, streamlining the entire process.

From what I’ve seen, the asset hierarchy structure is another feature that receives positive attention. This structure aligns well with preventive maintenance reliability concepts, and users seem to appreciate how it allows for automatic addition of preventive maintenance (PM) tasks based on asset class. G2 reviewers frequently highlight how this automation helps keep maintenance schedules dynamically updated, reducing manual intervention and ultimately enhancing equipment reliability.

Mobile accessibility is also frequently mentioned as a strong suit by G2 users. The intuitive mobile interface allows users to track work orders, update maintenance tasks, and manage assets on the go. This functionality is especially valued by technicians working in large facilities who require real-time updates and quick access to critical maintenance information. There’s a lot of love for how this tool handles mobile accessibility, with many reviewers noting its positive impact on productivity.

According to G2 user reviews, Accruent Maintenance Connection is respected for its asset management depth, though financial tracking could be more flexible. Some users mention that not being able to assign multiple cost codes to a single work order makes it harder to allocate expenses across departments.

Another theme in G2 feedback relates to customization and notifications. Reviewers note that while the platform performs well with its core modules, large-scale deployments would benefit from more admin control over rules and report customization. A few also mention delays or inconsistencies in work order alerts, which can impact scheduling efficiency.

Overall, G2 sentiment reflects Accruent Maintenance Connection as a capable and reliable CMMS, with strengths in asset and maintenance management that continue to stand out despite requests for greater flexibility.

What I like about Accruent Maintenance Connection:

- A standout capability, according to G2 reviewers, is the seamless SAP integration for asset parts ordering, which eliminates manual tracking and helps maintenance teams manage inventory efficiently without delays.

- I’ve noticed that G2 users really appreciate the asset hierarchy structure, especially how it aligns with preventive maintenance concepts and automatically adds tasks based on asset class, reducing manual effort and keeping schedules updated.

What G2 users like about Accruent Maintenance Connection:

"The customer service during development and implementation was very responsive. They were willing to collaborate with us as a vendor to tailor the configuration to our needs. The software is intuitive and feature-rich, going beyond just asset management, preventive maintenance, procedures, and task tracking. It even includes a project module for handling group service requests and tracking costs."

- Accruent Maintenance Connection Review, Ron M.

What I dislike about Accruent Maintenance Connection:

- Centralized maintenance data management stands out in G2 reviews, with many users appreciating how it consolidates asset-related information into one place, improving efficiency in tracking and managing operations.

- I’ve seen several G2 reviewers highlight the AI Maintenance Assistant, Tony, as a standout feature, praising its ability to provide instant answers and streamline maintenance processes.

What G2 users dislike about Accruent Maintenance Connection:

"The reporting feature could use an upgrade to save changes once a field is added. I run reports daily and have to keep adjusting the fields, even though I've set them to "year to date."

- Accruent Maintenance Connection Review, Verified User in Machinery

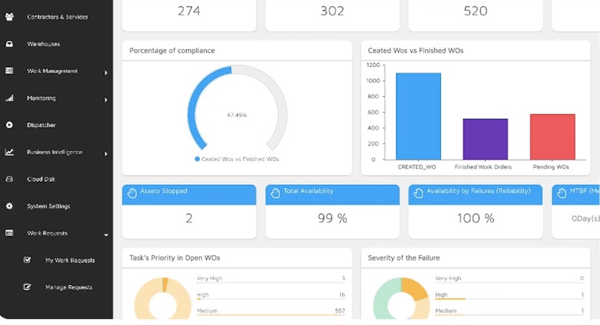

7. Fracttal One: Best for predictive maintenance and IoT integration

Fracttal One is a CMMS designed to manage comprehensive asset maintenance, and from the feedback I’ve reviewed, users appreciate its dynamic and user-friendly interface, which makes it accessible to both experienced and less-experienced maintenance managers alike.

Based on 259+ verified G2 reviews, Fracttal One has earned a customer satisfaction score of 55, with 93% of users saying they are likely to recommend it to others for asset performance management, task tracking, and work order management.

A centralized maintenance data management system is a standout feature. I’ve noticed that G2 reviewers frequently highlight the benefit of having all maintenance-related information—assets, work orders, spare parts, and performance metrics—in one place. This integration simplifies the tracking and management of operations, reducing the need for multiple systems or spreadsheets and streamlining maintenance processes.

The preventive and predictive maintenance scheduling feature also receives positive feedback from G2 users. Many reviewers praise how the system allows businesses to set up automated maintenance schedules, helping them proactively maintain assets and reduce the risk of unexpected breakdowns. This capability ultimately leads to better asset reliability and performance, a key benefit that’s often mentioned in user reviews.

Another feature that consistently receives praise is the ability to access maintenance records, update work orders, and track spare parts consumption in real-time via mobile devices like smartphones and tablets. Users highlight how this flexibility enables maintenance teams to respond quickly to issues, which is particularly beneficial for teams in the field or those requiring on-the-go management.

One feature that G2 reviewers seem to really appreciate is Tony, the AI Maintenance Assistant. This intelligent virtual assistant enhances productivity by quickly answering maintenance-related queries and helping users complete tasks more efficiently. Multiple users on G2 have praised how this AI-driven functionality speeds up task completion and reduces the need for manual searches.

According to G2 user reviews, Fracttal One is praised for its modern design and preventive maintenance tools, though measurement functionality could be more advanced. Some users mention the absence of dedicated features for tracking vibration or electrical parameters, which limits trend analysis for early fault detection.

Another recurring theme in G2 feedback is around performance and integrations. Reviewers note that the platform can load slowly with very large datasets, and the current unidirectional API restricts data exchange to inbound flows only. Many suggest that a bidirectional API would greatly improve integration with ERPs and other business systems.

Overall, G2 sentiment reflects Fracttal One as an innovative and reliable CMMS, with strong usability and preventive maintenance features that continue to win over users despite these limitations.

What I like about Fracttal One:

- Centralized maintenance data management stands out in G2 reviews, with many users appreciating how it consolidates asset-related information into one place, improving efficiency in tracking and managing operations.

- I’ve seen several G2 reviewers highlight the AI Maintenance Assistant, Tony, as a standout feature, praising its ability to provide instant answers and streamline maintenance processes.

What G2 users like about Fracttal One:

"It is a highly versatile tool for controlling, monitoring, and planning maintenance activities. It enables the integration of personnel, suppliers, customers, equipment, tools, materials, costs, execution times, and frequency. Additionally, it supports the automation of maintenance tasks."

- Fracttal One Review, Heder G.

What I dislike about Fracttal One:

- I’ve noticed that G2 users often mention the measurement points functionality as a limitation, particularly with its lack of advanced tools for tracking vibration or electrical parameters in motors, which impacts predictive maintenance capabilities.

- A common concern raised by reviewers is the unidirectional API integration, which can receive data but cannot send it back, limiting its ability to fully integrate with ERPs and other business systems.

What G2 users dislike about Fracttal One:

"Fracttal One could improve the speed of loading information, as it can sometimes be slow."

- Fracttal One Review, Hosayn R.

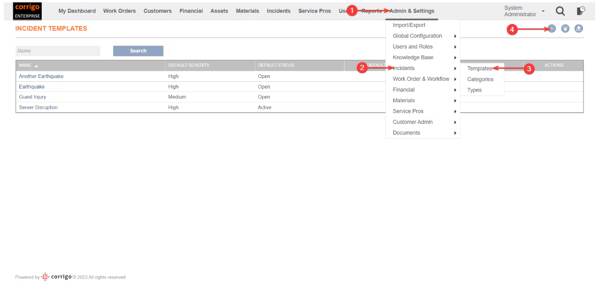

8. Corrigo: Best for vendor co-ordination and facilities management

Corrigo is a comprehensive CMMS designed to help facility managers effectively manage work orders, asset tracking, and vendor relationships at scale.

Based on 56 verified G2 reviews, Corrigo has achieved a market presence score of 54, with 92% of users likely to recommend Corrigo at a rate of 92%.

From the G2 reviews I’ve analyzed, users often highlight the platform’s strength in supporting high-volume environments, where managing multiple assets and coordinating maintenance activities is essential.

One feature that stands out in the feedback I’ve reviewed is its ability to capture and organize vast amounts of data. Users consistently praise how the system allows them to store detailed information on physical buildings, equipment assets, and both preventive maintenance (PM) and demand work. G2 reviewers seem to appreciate the ease with which they can manage maintenance schedules and track the status of work orders and assets, which streamlines operations.

Another element that frequently receives positive feedback is customization. Many users highlight the platform’s flexibility, which allows them to tailor it to meet the specific needs of different facilities. Whether adjusting workflows, creating unique asset tracking parameters, or managing various types of maintenance tasks, G2 reviewers often mention that Corrigo enables users to adapt the system to their operational requirements.

From what I’ve seen, G2 users also appreciate Corrigo’s ability to centralize work orders, communication, and invoicing. This unified platform provides businesses with insights into their expenditures and helps identify trends or issues impacting their bottom line. Many users note that having all relevant data in one place simplifies the process of analyzing costs and uncovering inefficiencies, which ultimately improves financial visibility.

According to G2 user reviews, Corrigo is valued for streamlining facility management, though emergency assignments could be more flexible. Some users note that only one technician can currently be assigned to on-call work orders, which can be limiting for multi-skilled teams handling diverse emergencies.

Another theme in G2 feedback relates to integrations and customizations. Reviewers mention that custom integrations can take longer than expected to implement, and site-specific settings aren’t as flexible as they’d like since changes often apply across all properties.

Overall, G2 sentiment reflects Corrigo as a capable platform for managing facilities and work orders, with strong operational benefits that outweigh its integration and customization challenges.

What I like about Corrigo:

- A commonly appreciated element in G2 reviews is the platform’s ability to capture and organize vast amounts of asset data, which makes tracking work orders and asset statuses much more efficient and streamlined for maintenance management.

- Something G2 reviewers seem to really appreciate is Corrigo’s customization capabilities. These allow users to tailor workflows and asset-tracking parameters to meet specific needs, offering flexibility across different facilities.

What G2 users like about Corrigo:

"The response times to inquiries are quick, with seamless capability and knowledge. The thoughtful and inquisitive responses ensure customers get exactly what they need. This site is great for budgeting purposes and identifying areas where you're experiencing the most issues at your facility."

-Corrigo Review, Nicholas P.

What I dislike about Corrigo:

- I’ve seen multiple G2 reviewers mention the dual on-call assignment limitation, noting that the system only supports one technician per emergency work order. Expanding this to include multiple technicians with different specialties would improve efficiency.

- Based on feedback I’ve gathered, custom integrations are often pointed out as taking longer than expected, with users suggesting that a more streamlined implementation process would enhance the overall experience and speed up access to new features.

What G2 users dislike about Corrigo:

"Since the configuration settings are very granular, some can be difficult to find. It's easy to get lost in the numerous tabs and menus. I believe more intuitive categories or a search function for settings could make navigation easier."

- Corrigo Review, Verified User in Construction

9. eWorkOrders CMMS: Best for predictive maintenance scheduling

eWorkOrders CMMS is a user-friendly solution that aims to simplify work order management, asset tracking, and preventive maintenance tasks.

eWorkOrders has achieved a decent customer satisfaction score of 73, with 97% of users willing to recommend it to others for work order management, reporting dashboards, and preventive maintenance.

From what I’ve seen in G2 reviews, many users highlight the simplicity of the platform, making it an excellent choice for businesses that need an easy-to-use system without an overwhelming set of features. This simplicity seems particularly beneficial for teams where not everyone is tech-savvy, as the system integrates well into daily operations with little to no learning curve.

I frequently see G2 reviewers praise the query feature, which allows for efficient search and analysis of work order data. Many users find it helpful for filtering and retrieving specific information quickly, helping managers gain insights into work order trends, asset performance, and maintenance history. This functionality supports better decision-making and allows for optimized maintenance schedules, a feature that has received consistent positive feedback from users.

One standout capability I’ve encountered in G2 reviews is the trigger functionality. Users appreciate the level of customization it provides, enabling them to set up alerts whenever a customer creates a job via the customer login. Reviewers often mention the flexibility of this feature, as it allows teams to specify exact times, dates, and types of triggers, ensuring they only receive the most relevant notifications.

According to G2 user reviews, eWorkOrders CMMS is recognized for its ease of use and strong core maintenance features, though reporting flexibility could be stronger. Some reviewers note that while pre-designed reports are helpful, the lack of custom report generation limits the ability to tailor insights to specific business needs.

Another recurring theme in G2 feedback is around automation. Users mention that fields don’t auto-populate based on associated information, which can lead to extra manual entry, and vendor ticketing requires technicians to send requests manually rather than through an automated workflow.

Overall, G2 sentiment reflects eWorkOrders CMMS as a reliable and user-friendly maintenance platform, with automation and reporting seen as key areas where further enhancements could add even more value.

What I like about eWorkOrders CMMS:

- A consistent theme in G2 reviews is the simplicity and user-friendly design of eWorkOrders, which makes adoption easy, even for teams with limited technical expertise, ensuring smooth integration into daily operations.

- I’ve noticed that many G2 users appreciate the query feature, highlighting its efficiency in searching and analyzing work order data, which helps retrieve specific information and improve maintenance schedules.

What G2 users like about eWorkOrders CMMS:

"It’s a simple platform that suits our needs well. The other CMMS systems we reviewed had overly complex tools that would likely go unused based on our business needs and the skill level of our team. The option for an unlimited number of users is a game-changer, allowing even our entry-level technicians easy access to the platform without us needing to review the profit and loss every time we hire new staff. This was a major hassle with our previous platform, but EWO solved that issue."

- eWorkOrders CMMS Review, Logan C.

What I dislike about eWorkOrders CMMS:

- From what I’ve seen in G2 reviews, a common point of frustration is the lack of custom report generation in eWorkOrders. While pre-designed reports are available, users often feel the need for more tailored options to enhance the platform's flexibility.

- A frequent piece of feedback I’ve noticed is that eWorkOrders doesn’t auto-populate fields based on associated information, and many users suggest that automating this process would save time and reduce data entry errors.

What G2 users dislike about eWorkOrders CMMS:

"One primary concern is the learning curve associated with using the software. For individuals who aren't tech-savvy or used to working with digital tools, it may take some time and effort to become comfortable with the software's features and functionalities. This can lead to initial resistance and potentially slow down the adoption process."

- eWorkOrders CMMS Review, Verified User in Non-Profit Organization Management

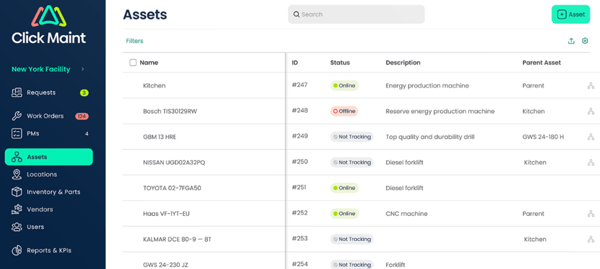

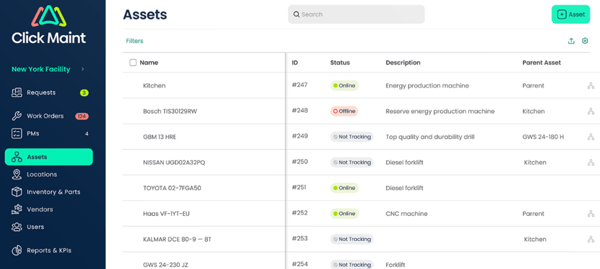

10. Click Maint CMMS: Best for simple maintenance scheduling and cost tracking

Click Maint CMMS stands out for its simplicity in tracking work orders, repairs, and scheduled maintenance. From what I’ve seen in G2 reviews, users frequently praise the system for its ability to automate notifications for upcoming tasks, which ensures that maintenance activities are never overlooked. Many G2 reviewers seem to appreciate this proactive feature for keeping maintenance on track.

Click Maint CMMS has achieved a customer satisfaction score of 68, with 96% of users willing to recommend it to others for work orders, approval management and preventive maintenance.

Based on feedback I gathered from G2 users, the reporting module is often highlighted as a key strength. Users find it incredibly helpful for managing maintenance costs and streamlining budget tracking. Multiple reviewers mention that the software’s asset tracking capabilities, including usage and condition monitoring, are valuable for planning future maintenance or replacements. Generating detailed reports within the platform seems to provide better insight into maintenance activities, which is appreciated by many users.

A common theme in G2 reviews is the ease of integration when transitioning to Click Maint from older systems. Many users note that the switch was smooth, with minimal disruption to daily operations. The well-supported onboarding process appears to facilitate a quick transition, allowing businesses to implement the system without significant IT resources or downtime.

I frequently see G2 reviewers highlight the mobile app's intuitiveness. Users especially appreciate being able to manage work orders and maintenance tasks from anywhere. This feature seems particularly valuable for teams with field technicians, providing flexibility for on-the-go management.

According to G2 user reviews, Click Maint CMMS is appreciated for its user-friendly design and mobile accessibility, though some note the mobile app could be more feature-rich. Compared to the desktop version, reviewers mention that advanced functionality would improve the experience for mobile-first users.

Another recurring theme in G2 feedback is around predictive and inventory features. Users point out that the absence of AI-driven maintenance tools limits proactive insights, and the inventory system, while functional, could be expanded with restocking alerts and procurement integrations to better support efficiency.

Overall, G2 sentiment reflects Click Maint CMMS as a reliable and accessible platform for maintenance teams, with opportunities to further strengthen its value through predictive analytics and deeper inventory management.

What I like about Click Maint CMMS:

- One standout capability, according to users, is Click Maint’s ability to track work orders, repairs, and scheduled maintenance, with automated notifications for upcoming tasks helping to stay proactive and organized.

- I’ve seen G2 reviewers highlight the reporting module as a key feature, particularly for managing maintenance costs and budgeting. This module makes it easier to track asset usage and generate detailed reports to analyze activities and costs.

What G2 users like about Click Maint CMMS:

"The best thing about Click Maint is how easy it is to manage work orders. Our implementation was straightforward, with only 6 users, and we were set up and managing work orders in about two weeks. The preventive maintenance feature is also simple to use and set up. The users love the mobile app as well."

- Click Maint CMMS Review, John R.

What I dislike about Click Maint CMMS:

- From what I’ve seen in G2 reviews, many users feel that the mobile app could benefit from more advanced features. Some suggest that adding functionalities available in the desktop version would improve the experience for field technicians.

- I’ve noticed that inventory management is another area that could be improved. Users often mention the need for features like automatic restocking alerts and better integration with procurement tools to enhance operational efficiency and streamline inventory tracking.

What G2 users dislike about Click Maint CMMS:

"I would like to see more features in the mobile app, as not all the features available on the desktop version are currently accessible on mobile."

- Click Maint CMMS Review, Matt T.

Best CMMS Software: Frequently Asked Questions (FAQs)

1. What are the two types of CMMS?

The two primary types of CMMS are on-premise and cloud-based. On-premise CMMS is installed locally and gives full control but requires IT support, while cloud-based CMMS is hosted online, offering automatic updates, scalability, and remote access.

2. How does CMMS software work?

CMMS software centralizes maintenance operations by tracking work orders, assets, and preventive maintenance schedules. It improves efficiency with automation, reporting, and inventory control, helping reduce downtime and extend asset lifespan.

3. Is Excel a CMMS?

Excel can track basic maintenance tasks, but it lacks automation, real-time notifications, and scalability. A true CMMS like MaintainX or UpKeep provides structured workflows, advanced reporting, and integrations that spreadsheets cannot match.

4. Which is the best free CMMS software?

UpKeep offers a free plan for small teams that includes core maintenance management functions. For businesses wanting more advanced functionality, free trials from vendors like MaintainX or Fiix CMMS can help evaluate fit.

5. Which is the best mobile CMMS software?

Top-rated mobile CMMS apps include MaintainX, Limble, UpKeep, and Fiix CMMS. These platforms are optimized for smartphones, enabling technicians to manage work orders, assets, and updates in real time.

6. How long does it take to implement CMMS maintenance software?

Implementation can take a few weeks for small companies with minimal data migration. Larger enterprises may require several months due to complex asset hierarchies, training, and customization needs.

7. Where can I find the best CMMS app for contractors?

Contractors benefit most from Click Maint CMMS for simple scheduling and cost tracking, or MaintainX for quick work order creation. Both are affordable, mobile-friendly, and suited for fast-moving contractor workflows.

8. What is the leading CMMS for equipment maintenance in the U.S.?

In the U.S., Fiix CMMS and Limble are popular choices due to strong equipment management and AI-powered maintenance automation. They help optimize uptime, extend asset lifespan, and provide actionable analytics.

9. What is the best-reviewed maintenance management systems app?

Based on G2 reviews, MaintainX and Limble consistently score high for ease of use, speed of setup, and customization. Users highlight intuitive mobile apps and flexible dashboards as standout features.

10. Which is the best CMMS provider for large corporations?

For enterprise-scale needs, Accruent Maintenance Connection and eMaint CMMS are preferred. They offer compliance tools, complex asset lifecycle management, and robust integrations with ERP systems.

11. What are the top computerized maintenance management systems for manufacturing?

Manufacturers often use Fracttal One for IoT-driven predictive maintenance and Corrigo for vendor coordination. These tools help minimize downtime, streamline compliance, and integrate with production systems.

12. What is the best CMMS software for small businesses?

Small businesses benefit from Click Maint CMMS and SecureDocs, which offer affordable, simple setups with preventive maintenance scheduling and cost tracking. These tools are easy to adopt without heavy IT involvement.

13. What’s the best value CMMS for a tech startup?

Tech startups often lean toward UpKeep for its affordable mobile-first approach and cloud access. MaintainX is another cost-effective choice, especially for teams prioritizing fast setup and intuitive UI.

14. What is the best maintenance management software for medium-sized firms?

Fiix CMMS is well-suited for mid-sized businesses with its AI-driven analytics, while Limble offers customizable workflows to match growing operational needs. Both balance depth with scalability.

15. What is the best cloud-based CMMS solution?

UpKeep and Fracttal One are top cloud-first solutions, offering offline mobile access, predictive maintenance, and quick scalability. Cloud hosting ensures automatic updates and easy multi-location access.

16. What is the most reliable CMMS tool for industrial operations?

Industrial teams favor eMaint CMMS for compliance reporting and asset hierarchies, or Accruent Maintenance Connection for advanced lifecycle management. Both deliver reliability for large-scale, regulated environments.

Equipment breaks, but your sanity doesn’t have to!

After thoroughly evaluating the best CMMS solutions, I’ve come to appreciate just how much the right system can transform maintenance operations. Each platform offers unique features tailored to different needs—whether you’re focused on asset tracking, predictive maintenance, or improving team collaboration. With so many options available, there’s always a solution that can streamline your maintenance processes.

But here’s the reality—no matter how efficient your CMMS is, maintenance will always be an ongoing task. Equipment will break down, work orders will pile up, and unexpected issues will arise. Without a CMMS, managing all of this can be overwhelming. Yet, with the right system, you can stay ahead, reducing downtime and keeping operations running smoothly.

I hope my insights help you find the right CMMS for your organization—because, let’s face it, no one likes dealing with constant maintenance headaches!

Integrating robust help desk software with your CMMS can help you address issues faster and keep operations running smoothly.

.png?width=400&height=150&name=Untitled%20design%20(56).png)

.png)