April 15, 2020

by Jason Kerner / April 15, 2020

by Jason Kerner / April 15, 2020

As the transportation landscape evolves — including the need to remain agile in shifting market conditions, increased expectations from customers for faster shipping, and more concerted efforts to improve environmental sustainability — many supply chains are turning to freight visibility to gain real-time, actionable data.

For years, supply chains have attempted to gather better and more accurate information about their transportation processes. Many have relied on cumbersome manual efforts that put a strain on employees and resources, and in the end, only deliver pieces of siloed data.

Ever since transportation visibility emerged within the last decade, adoption has surged. The technology is quickly becoming a foundational component of supply chain strategies.

In the past, supply chains have used transportation visibility to gain a competitive advantage by providing customers with insights in real-time.

However, in recent years, customers have come to expect visibility. With 70% of customers expecting the ability to track shipments and gain updates on the progress of the delivery, shippers have turned to real-time visibility to help them meet the rapidly growing customer demands for faster, less expensive, and more transparent delivery.

While buzz around transportation visibility has grown as leading shippers use it to transform their supply chains, many aren’t sure exactly what visibility is and how it works. This introduction will outline a few of the key supply chain challenges transportation visibility solves as well as how it actually delivers outcomes.

Real-time transportation visibility has become a key aspect of global supply chain strategies. In a complex industry, where various intertwined partners and third parties are involved, it’s hard to gain enough insight into the process to make effective decisions.

Real-time visibility creates a connective tissue between the transportation ecosystem. By increasing collaboration and data sharing relationships, companies can both proactively handle short-term challenges and build optimized long-term supply chain strategies.

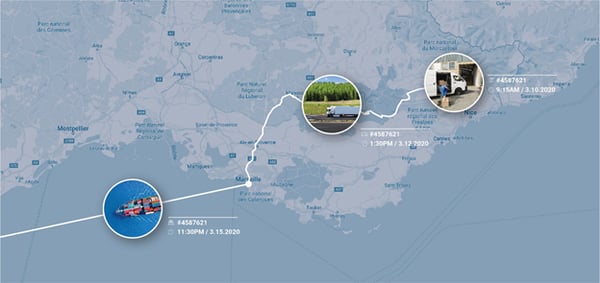

While freight visibility offers various benefits, real-time shipment tracking is at the core. The ability to know where a shipment is at any point in time and when it will arrive at its destination is essential.

While supply chains have been able to gain some shipment location information in the past, it has been based on outdated and incomplete data. Gaining complete, accurate, and real-time data – also known as high-fidelity data – is what allows stakeholders to proactively manage exceptions.

Additionally, visibility is about more than dots on a map. Customers, dock managers, store managers, and numerous other stakeholders need to know when a shipment will arrive. A retail store needs to prepare for the shipment’s arrival without wasting labor. If a manufacturer doesn’t have certain materials on time, they could be forced to halt production. Having insight into delayed shipments can help shippers make adjustments to downstream supply chain activities, such as moving dock appointments to avoid fees.

When the data is available instantly and stakeholders are notified of certain milestones or events through automated alerts, supply chains are able to shift to a proactive approach and manage exceptions much more effectively.

Visibility data can also help with dispute resolution. Carriers and shippers might have different definitions. For example, does “on time” mean when the driver entered the facility or when they actually get through the line and to the dock? Tracking data shows exactly where the truck was and when, so all parties can gain alignment and figure out where the delay occurred.

Real-time visibility and predictive estimated time of arrival (ETA) are essential for supply chains to increase efficiency and agility.

In the past, it has also been challenging to gain visibility across a company’s entire supply chain – across all modes and geographies. Without this complete view, supply chains are only getting a piece of the puzzle, limiting their ability to optimize operations.

With many supply chains relying on a global approach, transportation information shouldn’t be siloed. With a view across regions, supply chains can better understand the entire journey their freight takes.

In additional to global reach, visibility across modes helps supply chains monitor all of their shipments. While many shippers already use different modes for different needs, market volatility is increasing the need for modal flexibility. Real-time transportation visibility helps shippers gain complete freight visibility across modes.

Connecting to an entire carrier network is challenging. Shippers often distribute their loads across various carriers and 3PLs work with thousands. Many use manual tracking methods, such as calling the driver for location updates and then passing that information to customers with an email.

To avoid these manual tracking efforts, some build connections to each and every carrier in house is labor and resource intensive. Not only do companies struggle to set up all of these connections, they have a hard time maintaining them and ensuring they’re receiving high-fidelity data.

On the other side, carriers are being asked to connect with various customers and visibility providers. Building scalable connections or using different apps for each customer is overwhelming and time-consuming.

Transportation visibility allows supply chains to avoid these manual and time-intensive processes, enabling them to focus their time on more strategic initiatives.

Even more complex than connecting to carriers, an age-old supply chain challenge is gaining insight into inbound shipments from suppliers. This is a large blind spot that can have a substantial impact on downstream supply chain plans and activities.

Without control over the shipment, shippers struggle to obtain real-time information about its status or estimated arrival. Instead of contacting the carrier for updates, they are reaching out to the supplier, who then has to reach out to the carrier.

Real-time visibility helps bridge this gap and deliver tracking and predictive ETA insight directly from the supplier’s carrier to the shipper that’s anticipating the shipment. With this collaboration and insight into inbound shipments, supply chains can improve planning and make adjustments to downstream activities as needed.

While many shippers have started to use transportation visibility for the ability to manage exceptions and proactively adjust plans before issues occur, supply chains are now using the data that is being collected for business intelligence.

Many are using this data by carrier or lane to evaluate performance. For example, a shipper can use past shipment data – such as on time rates, lane performance, and trends by location and time of day – to identify the root cause of issues or areas that are especially efficient.

Gaining insight into in transit inventory can also help shippers better manage inventory. Supply chains can monitor their shipment data over time to more accurately calculate lead times. Because supply chains have a better idea of where their orders are and how long it takes them to arrive, they can increase inventory management efficiency and lower holding costs.

With manual or outdated tracking methods leaving gaps in the data, shippers haven’t been able to glean insights and use it in a strategic way. By using transportation visibility data along with other supply chain insights, companies can evaluate their entire supply chain network, finding areas where they can improve.

Supply chains have been using some form of tracking information for years. However, real-time data and predictive insights have only become available with the emergence of transportation visibility technology.

So, what makes transportation visibility more effective than past tracking methods? Modern technology enables a more automated and real-time flow of data. Real-time visibility solutions focus on establishing strong connections to a large network of carriers, leveraging machine learning based on high-fidelity data, and ensuring stakeholders can access real-time insights in an actionable format.

Connecting to carriers is not easy. If it were, everyone would already have complete freight visibility. Because the value of visibility hinges on the ability to gain data from carriers, it’s essential to build strong and scalable connections that will gather the accurate and real-time data that’s needed to take action.

In order to gain visibility across carriers, providers leverage several different types of connections:

For years EDI, or electronic data interchange, was used to gain information about a shipment’s status. However, EDI technology delivers data in batches, creating data delays and incomplete information. Modern technology, such as APIs, has given rise to real-time transportation visibility, reducing the need for slow or manual processes and technologies.

A big benefit of transportation visibility is knowing when freight will arrive at its destination. Knowing that it will be late is helpful, but gaining insight into when it will actually arrive is what allows stakeholders to make proactive decisions and change course as needed.

An ETA isn’t a data point passed through the carrier. Calculating an accurate ETA is complex because it needs to consider many factors — from the weather and the driver’s hours of services to road closures and more.

Transportation visibility uses artificial intelligence and machine learning models that take advantage of the hundreds of millions of historical data points. The model places these data points into buckets based on dozens of unique attributes, including shipper, consignee, lane, distance from location, carrier, time of day, day of week, weather and traffic conditions, driver hours of service, and many more.

The model then identifies the bucket that is most similar to the shipment that is currently being tracked and will use the data points within that bucket to calculate a weighted average, resulting in the ETA.

Through the power of machine learning and numerous data points, transportation visibility helps stakeholders predict outcomes and make decisions based on the most accurate ETAs.

All of this visibility data is only powerful if all the necessary stakeholders can access it in real-time and in a format they can understand. This means all of the tracking data is normalized and enriched and is delivered in a digestible format — without any lag time.

Real-time visibility solutions automate this step to ensure supply chains have the data they need, when they need it, without manual intervention. There are two key ways supply chains access transportation visibility data:

Transportation visibility is no longer a nice-to-have. Not only have customers come to expect real-time insight into their shipments, comprehensive visibility enables supply chains to take control of their transportation processes, leading to a more efficient and effective supply chain.

With high-fidelity visibility data, supply chains can improve exception management, predict transportation outcomes and delays, derive more actionable business intelligence, and improve collaboration across the supply chain.

While modern transportation visibility, or advanced visibility, has become a strategic priority for supply chains over the last few years, shippers and 3PLs are still only scratching the surface when it comes to the insights they can derive. With the right solution and approach in place, real-time visibility has the power to transform supply chains.

Stay up-to-date with the latest supply chain planning software to help with your company's unique needs.

Jason Kerner is the VP of Solutions Engineering at project44, an advanced visibility provider, where he leads the global team that helps leading shippers and logistics service providers gain value from their transportation visibility investment.

Talent management isn’t just another industry buzzword the big shots in Silicon Valley are...

by Lauren Pope

by Lauren Pope

Has anyone ever told you they “owe you one”?

by Maddie Rehayem

by Maddie Rehayem

With more and more businesses employing rapid application development (RAD) workflows,...

by Holly Landis

by Holly Landis

Talent management isn’t just another industry buzzword the big shots in Silicon Valley are...

by Lauren Pope

by Lauren Pope

Has anyone ever told you they “owe you one”?

by Maddie Rehayem

by Maddie Rehayem