October 25, 2019

by Connie Benton / October 25, 2019

by Connie Benton / October 25, 2019

You have a great idea, you draw amazing illustrations for your product, your community supports it financially, and you’re overbooked.

When you get down to work, you end up delaying shipment for months because of manufacturing and logistics.

It sounds like something you won’t ever encounter, but this story is relatable for 75 percent of startups, because that percentage of crowdfunding projects fail to deliver on time.

Setting up your manufacturing workflow beforehand ensures you make it with the other 25 percent. Follow these seven steps to help prevent your startup from delaying shipments.

Many startups suffer from a DIY attitude. The founders know a lot about the product itself, and they think they can manage to control every other aspect of the business as well. They think that there’s no need to hire a consultant, as they can research the web and figure it out.

However, you’re already learning from somebody else when you’re reading guides online. So why not take it to another level and consult a person who knows more about manufacturing than you do?

Even if you have to pay them, the pitfalls they tell you about could cost you ten times the consultation price tag in the long run. Find a friend or expert who either has the experience of launching a startup or works in manufacturing or logistics. Talk to them about your plans; their constructive criticism will make the whole picture clearer for you.

Your product design may look amazing in drawings, but it has to be manufactured with real materials. What if the type of plastic you were initially going for gets dirty easily or looses its matte coating? You won’t know that unless you test dozens of materials.

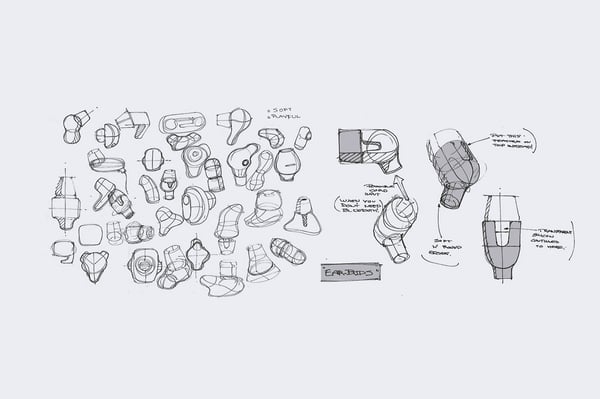

Source: Viggo Blomqvist/Behance

Source: Viggo Blomqvist/Behance

Ask your local manufacturers for samples to know your options. Need consultation when creating your product? Find out if using a product design service provider is the right move for you.

Before you can start looking for a manufacturer, you need to develop a prototype of your product. It doesn’t have to be exactly as you envision it; the only thing you need is a minimal viable product.

This is one of the most important stages of the product development cycle. You want to perfect the product before you start mass manufacturing, and working on the prototype lets you go through multiple iterations that will take you to the final form of the product.

The problem is, not all products can be manufactured in your garage. For example, creating a pair of wireless headphones or a powerful laptop is much more complex than making a lamp or a wallet. Printed circuit board (PCB) design adds another layer of intricacy, making it difficult to build the prototype in a simple DIY setup. If you're unable to create the prototype yourself, you'll need to combine this step with the next: finding the right manufacturer. Once you do, you might be able to persuade them to produce the prototype for you.

|

TIP: Ready to start designing your product? Find the best product and machine design software to create your prototype. |

Looking for a manufacturer is a long and hard process. The problem isn’t about finding a manufacturer, there are thousands of them all around the world. The problem is finding the one that fits all your needs.

Look for the following elements in a manufacturer:

|

Now, many people can’t decide whether they should look for a local or overseas manufacturer. There is no definite answer to this question.

If you’re the kind of person who thinks in terms of being in the black, not giving jobs to locals, that question is about cost, not about country.

If an overseas manufacturer in China or Africa is reliable and costs you less per product – even including shipping – you shouldn’t bail on them simply because of delivery time. On the other hand, if you need super fast delivery, and a manufacturer you can check with personally every few days, your only option is choosing a local one.

In the end, it all depends on the bottom line and your needs.

The ultimate advice when it comes to choosing a manufacturer is getting prepared to compromise. Sometimes, you can’t have it all. When you have your checklist ready, here are some website to find a manufacturer. There are more out there, but these can get you started.

You can always just perform a quick Google search for your local manufacturers. You’ll typically land on a local directory, but it’s going to be less informative than the websites above. The other option is contacting a local association of manufacturers.

Don’t choose the first good manufacturer you find. Compile a list of several manufacturers and contact them to get a quote. Treat it as a beginning of your long-standing relationships. Below are questions you should ask the manufacturers – apart from the price and time it would take to complete your order.

|

These answers, and the price of manufacturing, should help you form a decent understanding of whether you should work with the company or not. Search for reviews online or contact clients to check if their reputation is good enough.

Even the most reliable manufacturer won’t solve your problems if the product arrives from the factory to the customer a week late. You need to plan everything in the manufacturing and delivery process to make sure your clients or backers stay happy.

It's a good idea to use supply chain planning software to estimate the amount of time it would take for the manufacturer to complete your order, turn it to the delivery company, and for your team to process individual deliveries.

You may also want to throw a CRM system in the mix to help streamline processing deliveries to your backers and working with complaints. The planning process includes finding reliable delivery services to estimate the cost and delivery time, and making sure you have enough people working on processing delivery to backers.

Ideally, you should keep the number of things that slow down each stage to the minimum. Pay close attention to what it takes to pass the products to the next stage; it’s where most of the problems come from.

Receiving a sample of the manufacturer’s product, or even getting a prototype done for you, gives you a glimpse into the quality of the product you’re going to receive.

However, it tells you nothing about its reliability in practice. The only way you can learn that is by making a test order. This will show you the true quality of mass-manufacture products the company is able to produce and test their ability to deliver on time.

Start with ordering the minimum quantity before you sign a contract for more products. Don’t worry if MOQ is too high. In most cases, you’ll be able to negotiate it.

If you’ve had any misconceptions about manufacturing, they’re now shattered. This process is more than just having a great idea and outsourcing it to a factory. It takes a lot of research and planning, but, in the end, you will outperform most startups in both quality and delivery time.

Start planning your process today by finding the right manufacturing execution system for your brand.

Connie is a chief content writer, guest contributor and enthusiastic blogger who helps B2B companies reach their audiences more effectively. With an emphasis on organic traffic and conversion, she takes big ideas and turns them into highly practical content that keeps readers hooked.

Ask any manufacturer what they think of manufacturing sales; they'd reply to your question...

by Sabine Kempe

by Sabine Kempe

Digitalization across all industries has never been more of a hot topic.

by Anouschka Kelsey Patel

by Anouschka Kelsey Patel

To manage manufacturing operations, most manufacturers use ERP (enterprise resource planning)...

by Gabriel Gheorghiu

by Gabriel Gheorghiu

Ask any manufacturer what they think of manufacturing sales; they'd reply to your question...

by Sabine Kempe

by Sabine Kempe

Digitalization across all industries has never been more of a hot topic.

by Anouschka Kelsey Patel

by Anouschka Kelsey Patel