October 23, 2025

by Washija Kazim / October 23, 2025

by Washija Kazim / October 23, 2025

3D printing is awesome, until your software turns it into a nightmare.

I learned this while evaluating some of the best 3D printing software. One moment, you are excited to slice a model; the next, trapped in a confusing mess of settings, error messages, and prints that look nothing like they should.

Now, I’m not a 3D printing expert. I don’t spend my days obsessing over layer heights or tweaking temperature settings (though I now have a newfound respect for those who do). But what I do know is software, what makes it user-friendly, what features actually matter, and what’s unnecessary fluff.

3D printing software refers to the tools and applications used to create, prepare, and manage files for 3D printing. At a high level, these solutions help convert digital designs into machine instructions that a 3D printer can understand. The category includes three primary types of software:

Understanding these categories helps you choose the right tool for your workflow, whether you’re designing complex parts, preparing print models, or overseeing printer performance.

I evaluated and compared some of the most popular 3D printing tools, based on G2 reviews, to see which ones stand out.

I scrolled through hundreds of reviews about everything, from beginner-friendly slicers to advanced modeling tools, focusing on usability, features, and overall printing success.

Whether you’re a total newbie, a serious maker, or somewhere in between, here are my top picks for the best 3D printing software solutions that are worth your time.

Onshape: Best for cloud-based CAD and real-time collaboration

Enables seamless teamwork and data management for design from any device.

($1,500/user/year)

Autodesk Fusion: Best for integrated design, manufacturing, and simulation

Combines 3D modeling, engineering, and production tools in one platform.

($680/user/year)

Siemens NX: Best for advanced 3D design and engineering

Offers a comprehensive suite for complex product design and innovation.

($614.25/month)

Solid Edge: Best for flexible workflows with synchronous technology

Delivers a hybrid modeling approach that enhances design versatility.

($261/month)

SOLIDWORKS: Best for user-friendly 3D design and simulation

Simplifies complex modeling and supports robust data management.

($2,820/year)

Tinkercad: Best for beginners and educational use

Provides an intuitive, browser-based platform for quick 3D design projects.

(Free)

Ultimaker Cura: Best for reliable 3D printing preparation

Streamlines model slicing and printer optimization for consistent results.

(Free)

*These 3D printing software solutions are top-rated in their category, according to G2's Winter 2025 Grid Report. I’ve also included their monthly/annual pricing to facilitate easier comparisons for you.

The global market for 3D-printing software is still relatively modest but growing rapidly — one recent estimate places it at about $1.17 billion in 2025, projected to reach around $4.15 billion by 2034 at a CAGR of ~15%.

3D printing feels like magic. You start with a digital design, press a few buttons, and bam, your idea becomes a physical object. But as I quickly learned, it’s not as simple as dragging a file into your printer and hoping for the best.

At its core, 3D printing software serves as the intermediary between your design and your printer. Some programs let you create and edit 3D models from scratch, while others focus on slicing, basically, breaking your model down into printable layers and generating the right instructions for your printer. And then there are all-in-one solutions that do a mix of both.

Since I don’t design intricate 3D models for a living, I focused on how well these tools strike a balance between power and usability. I wanted to see which ones make the process easy for beginners, which ones give pros the advanced tools they crave, and which ones make things harder than they need to be.

I wanted to understand what makes 3D printing software great (or frustrating), so I went beyond surface-level impressions and started investigating real user experiences.

I reviewed G2 grid reports, which provided a clear view of how different 3D printing software ranked in terms of usability, features, and customer satisfaction. G2’s insights helped me understand which programs were actually delivering on their promises and which ones had consistent pain points. I also used AI to analyze hundreds of user reviews for different solutions to understand user sentiment beyond my testing.

This helped me narrow down a shortlist of the most promising and talked-about 3D printing software on G2. I also consulted a professional with hands-on experience and validated their insights using verified G2 reviews.

The screenshots featured in this article may be a mix of those obtained from the vendor’s G2 page or publicly available material.

3D printing should be fun and rewarding, not a mess of failed prints and confusing settings. I focused on a few key criteria during my evaluation to make sure I was recommending the best tools for different types of users.

By evaluating all the tools for usability, slicing performance, advanced features, stability, and print success rate, I could separate the seven best 3d printing software from the ones that make things harder than they need to be.

The list below contains genuine user reviews from G2’s best 3D printing software category page. To be included in this category, a solution must:

*This data was pulled from G2 in 2025. Some reviews may have been edited for clarity.

The 3D printing software listed below typically falls into two main categories: design (CAD) tools used to create 3D models and slicing software used to prepare models for printing.

The tools below represent the best options across each stage of the 3D printing workflow.

| Software | Primary Category | Best For | Key Strength |

|---|---|---|---|

| Onshape | Design (CAD) | Cloud-based collaboration | Real-time team editing in a browser-based environment |

| Autodesk Fusion | Design (CAD) | Integrated design & manufacturing | Combines parametric modeling, simulation, and CAM tools |

| Siemens NX | Design (CAD) | Advanced engineering workflows | High-end modeling, simulation, and enterprise manufacturing tools |

| Solid Edge | Design (CAD) | Flexible modeling workflows | Synchronous technology for rapid design changes |

| SOLIDWORKS | Design (CAD) | User-friendly 3D design & simulation | Industry-standard CAD with strong engineering ecosystem |

| Tinkercad | Design (CAD) | Beginners & education | Intuitive, drag-and-drop modeling in a browser |

| Ultimaker Cura | Slicing Software | 3D printing preparation | Converts 3D models into G-code with broad printer compatibility |

Onshape is a browser-based computer-aided design (CAD) platform that replaces traditional, clunky software models with a fully cloud-powered experience. Unlike traditional CAD programs that require hefty installations and constant file management, Onshape runs entirely in a web browser, meaning users can access their projects from literally anywhere, including their phone (which may feel unusual but works surprisingly well, according to G2 reviews).

G2 reviewers exploring Onshape for 3D printing workflows often note that its parametric modeling system is built for precision. Unlike mesh-based design tools like Tinkercad or Blender, Onshape relies heavily on defined constraints and exact measurements. This makes it incredibly powerful for engineers and professionals, but it can feel less intuitive for casual users or those accustomed to freeform modeling. While many appreciate the control it offers, there’s a learning curve if you're coming from a more visual or flexible design environment.

According to G2 Data, 96% of reviewers highlight Onshape’s cloud-based accessibility as a standout advantage, noting its seamless performance across devices without installation hassles.

Real-time collaboration is one of the most frequently praised features in G2 reviews of Onshape. Users highlight how changes made to a design are reflected instantly across devices, making it an ideal platform for team-based design work. The built-in version control also receives strong feedback, allowing users to easily revert to earlier iterations without manually managing multiple file versions.

From what I gathered through G2 reviews, users really appreciate how smoothly Onshape handles precision modeling and file exports. That said, many point out that Onshape isn’t a slicer. Once a model is finished, it still needs to be exported (usually as an STL or OBJ) for slicing elsewhere. Still, reviewers agree that the export process is seamless and supports all the standard formats, making it easy to integrate into existing 3D printing processes.

It’s also great that Onshape offers a free version, allowing users to explore its capabilities without a subscription. However, several reviewers mention the key limitation: you can only create public documents. This can be a dealbreaker for anyone working on private or proprietary designs. Even so, many see it as a fair trade-off for accessing powerful, cloud-based modeling tools at no cost.

Overall, Onshape shines for users who need structured, collaborative, and highly accurate modeling features. While it doesn’t replace a slicer or print-prep tool, reviewers find it excellent for mechanical design and precision work, and it fits seamlessly into a professional workflow when paired with the right complementary software.

“Onshape CAD tool is a web-based tool, so that it can be accessed from a Mobile platform too. Onshape has good tutorials to help new learners. Customer support is also very nice. DXF, STP, IGS, etc., and well-known 3D platform models can also be easily integrated. In assembly, we can assemble apart with a single fastened mate. It is a good implementation in CAD tools. "S" shortcut is good for frequent use of feature selection.”

- Onshape Review, Senthil N.

“The main downside is the speed of Onshape. Since it is in the cloud, its performance is not as snappy as that of a local CAD system, such as SolidWorks. This is mainly seen in assemblies. The second downside is part of its feature: Documents. Documents can get bogged down very quickly with part studios, assemblies, and derived parts.”

- Onshape Review, Sebastian S.

Explore the latest 3D printing statistics and trends to discover how the technology is being applied across various industries, from medical breakthroughs to large-scale production.

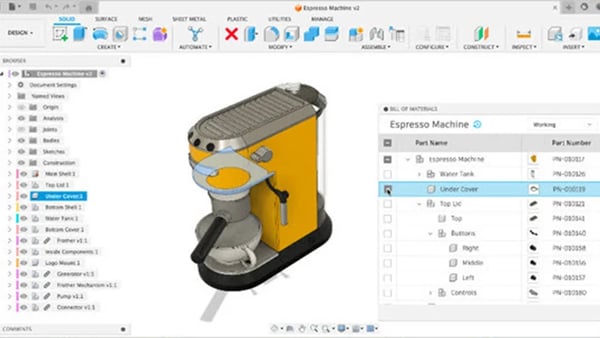

Autodesk Fusion is one of the most widely used CAD tools in engineering, product design, and manufacturing, but I wanted to see how well it works specifically for 3D printing. Since it combines parametric, direct, and sculpting modeling, it offers more flexibility than software that focuses solely on structured, mechanical design. Unlike simpler programs, it also has simulation, stress testing, and assembly tools, making it useful for designing functional parts rather than just decorative prints.

One feature that receives attention in G2 reviews is Autodesk Fusion's built-in slicer — a feature not commonly found in CAD platforms. Integrated within the Manufacturing workspace, it enables users to generate G-code directly within the software, eliminating the need to export files to a separate slicer. Reviewers say this works well for basic prints, but also note that it lacks the advanced controls and fine-tuning options found in dedicated 3D printing tools. It's convenient, but it may fall short for users who need more granular print settings.

For example, while you can set infill patterns and layer heights, it doesn’t have as many advanced support generation options. If you’re working on prints that require intricate support structures or highly optimized slicing strategies, you’ll probably still want to use a dedicated slicer.

G2 reviewers often highlight Autodesk Fusion’s mesh repair tools as a helpful feature for 3D printing workflows. For users dealing with non-manifold geometry, holes, or broken STL files, the built-in repair tool has been noted for catching common issues and offering automatic fixes, reducing the need for third-party tools like Netfabb. While some complex files still require manual cleanup, many users say Fusion’s repair process is efficient enough to make files print-ready in tools like Cura with minimal extra effort.

Another standout is the ability to switch between parametric and freeform modeling. Reviews frequently mention how this flexibility supports both precise engineering parts and more organic, sculpted shapes. Being able to switch between structured modeling and intuitive sculpting gives users more creative control compared to platforms that restrict them to a single workflow.

From what I gathered through G2 user reviews, Fusion’s interface is praised for being feature-rich and powerful, offering deep control for complex design work. That said, many note that the UI can feel dense and somewhat overwhelming for users who simply want to prepare a model for 3D printing.

Even simple edits may require navigating multiple menus, which can slow down the process for quick or casual projects. Still, most agree that once you get used to it, the depth of functionality is what makes Fusion so capable.

Reviewers also appreciate Fusion’s versatility and precision when working with its native file formats. However, performance tends to dip with large, high-poly STL files; users report noticeable slowdowns even on high-end systems. Still, many point out that for standard design and modeling tasks, Fusion remains smooth, reliable, and highly optimized within its own ecosystem.

“The amount of features available. My favorite feature is the sketch function. It works flawlessly when going from sketch to design. Additionally, the ability to import a canvas and calibrate it to nearly perfect accuracy is impressive. I can recreate multiple objects for 3d printing and change the design to what I need.”

- Autodesk Fusion Review, Aaron H.

“Two aspects of Autodesk Fusion 360 that I find less favorable are its dependency on an internet connection and its CAD file compatibility. While cloud-based software generally offers significant advantages, features like real-time collaboration and automatic saving can be challenging in areas with limited connectivity. Additionally, despite supporting many file formats, the conversion of files during export is often limited, resulting in the loss of details or geometries when importing to other software.”

- Autodesk Fusion Review, Juan M.

Great prints start with great designs, and understanding trends in graphic design can help you create more visually appealing and functional 3D models. Check out the latest graphic design statistics now.

Siemens NX offers a comprehensive engineering platform for aerospace, automotive, and high-end manufacturing applications. It’s strictly built for professionals who need precision modeling, advanced simulation, and direct control over additive manufacturing (AM) processes. What really sets it apart is its ability to handle complex, multi-material, and industrial-scale 3D printing workflows, which is something most CAD programs don’t even attempt.

G2 reviewers frequently call out NX’s integrated support for metal 3D printing as a standout feature. According to G2 Data, NX’s integrated 3D modeling capability scores 92%, while its standalone slicing functionality is rated 84%, indicating that users value its end-to-end additive manufacturing (AM) integration.

Unlike many tools that focus primarily on FDM, NX includes specialized workflows for processes like powder bed fusion (PBF), direct energy deposition (DED), and SLA. For metal printing specifically, users highlight the platform’s ability to automatically generate and optimize support structures based on thermal distortion and stress distribution. This level of precision is especially valuable in industries that use high-cost materials, such as titanium or Inconel. That said, for more standard FDM workflows, this level of complexity may be more than most users need.

G2 reviewers often highlight Siemens NX’s simulation-driven print preparation as a major differentiator. Unlike traditional slicers that simply generate toolpaths, NX simulates the full build process before printing begins. Users describe scenarios where the software predicts potential warping or heat-related distortion, especially valuable for metal or large-format industrial prints, where failed builds can result in costly material waste.

Another feature that stands out in reviews is NX’s hybrid manufacturing capabilities. The ability to combine additive and subtractive processes in a single workflow, such as printing a metal part with internal lattice structures and then refining outer surfaces via CNC simulation, is seen as a unique advantage. This makes NX particularly well-suited for industries where 3D printing is part of a broader production pipeline.

I observed in G2 user reviews that Siemens NX is widely respected for its powerful, enterprise-grade engineering capabilities. That said, its complexity can be a real hurdle; reviewers mention that even experienced CAD users can feel overwhelmed by the dense interface and deep functionality. Still, many agree that for professional engineers working on intricate designs, that same depth is what makes NX so valuable.

I also noticed that reviewers highlight that NX is clearly designed with enterprise users in mind. Unlike tools such as Fusion 360 or Onshape, it doesn’t offer a free or browser-based version, and the licensing costs are significant. However, users in high-precision industries note that the investment pays off with unmatched performance, accuracy, and advanced simulation tools.

“NX is a comprehensive, all-in-one tool to support my 3d printing workflow. This powerful program has everything I need to design and produce parts quickly and efficiently. With its intuitive interface, advanced 3D modeling capabilities, and integrated simulation tools, it's no wonder that this software has become my all-time favorite. Siemens NX helps me streamline the additive manufacturing process. Its features enable easy creation of complex geometries of any size or shape with precision and accuracy. It also includes automated simulations that can analyze material properties as well as design and machine compatibility issues before any part is produced.”

- Siemens NX Review, Areeb I.

“The most disliked thing about NX CAD is that it's not that user-friendly when we talk in the context of new users (educational purposes), compared to the other software, and getting the educational license is another problem that is quite easily available for Autodesk products. The reason is that most Autodesk products are preferred in India. One more thing that can be considered is the customer care support that is lagging in the case of the complete Siemens group, which is quite better than Dassault Systèmes.”

- Siemens NX Review, Anjan M.

Now that you’ve found the right 3D printing software, why stop at static models? Check out our list of the best animation software and start making your creations move.

Solid Edge is Siemens’s more accessible CAD solution, positioned between beginner-friendly software and full-blown engineering suites like NX. I wanted to see how well it works for 3D printing workflows, especially since it includes direct modeling, parametric design, and a dedicated 3D printing environment.

Unlike Onshape or Fusion 360, which focus on cloud-based collaboration, Solid Edge is a local install with an emphasis on traditional engineering workflows.

One feature that gets strong attention in G2 reviews of Solid Edge is its convergent modeling. This hybrid approach enables users to work with mesh-based STL files alongside traditional parametric CAD models, a capability that many CAD tools struggle with. Reviewers say it simplifies the process of editing STLs by blending mesh and precise geometry without requiring time-consuming conversions, making it especially useful for repairing and preparing 3D scan data.

Solid Edge’s dedicated 3D printing environment also stands out. Unlike most CAD tools, it allows users to send files directly to a 3D printer without the need for a separate slicer. According to users, the built-in tools offer quick checks for wall thickness, unsupported areas, and layer previews. While not as detailed as some slicing software, it’s considered a convenient option for fast print prep.

Reverse engineering capabilities are another highlight. G2 reviewers note that the platform includes mesh cleanup tools for turning rough scans into usable models. The automated smoothing and edge repair features help speed up the process; however, several users point out that manual cleanup is still necessary for more complex or low-quality scan data.

I observed in G2 user reviews that Solid Edge earns praise for its comprehensive toolset and engineering precision. That said, the interface is often cited as a point of pain. Many users find it cluttered due to the sheer number of features packed into the UI. Still, reviewers agree that once you adapt, the depth and power of the interface make it highly capable for professional design work.

From what I gathered from reviews, many users also appreciate Solid Edge’s strong compatibility with structured CAD workflows and its broad support for various file types. However, import and export performance shows room for improvement; large, high-polygon STL files can cause noticeable slowdowns. Even so, users note that for standard engineering models and precise mechanical designs, Solid Edge remains stable, efficient, and reliable.

“The most helpful thing about Solid Edge is the ability to easily map out your thoughts and ideas onto the screen with the tools that are available, be it 3D or 2D. The fact that the limited version is free is what further helped me to continue using this product for my personal work.”

- Solid Edge Review, Shayaan R.

“There are a few things that I don't like. Sometimes, I need to use a 3D DXF file, but I can't import it into Solid Edge because it doesn't support it. Another similar thing is importing .3mf (a popular file format for 3D printing) file that is not importable in SE.”

- Solid Edge Review, Imre S.

SOLIDWORKS is one of the most widely used CAD programs in engineering and product design; however, I wanted to see how well it specifically handles 3D printing. Unlike Fusion 360, which is more cloud-focused, or Siemens NX, which is built for full industrial workflows, SOLIDWORKS sits somewhere in between. It’s local software with strong parametric design tools, simulation features, and some helpful 3D printing integrations.

One thing G2 reviewers often point out about SOLIDWORKS is its highly customizable 3D printing workflow, which can be both a strength and a challenge. Unlike more automated tools that walk users through each step, SOLIDWORKS requires initial setup and configuration to function smoothly. That said, once properly set up, users appreciate the high level of control it offers over model prep, slicing previews, and print validation.

SOLIDWORKS’ Print3D tool gets a lot of positive attention in G2 reviews for making it easier to prep models for printing. It allows users to check printability, reorient parts, and preview slicing layers before export. Reviewers especially appreciate the built-in error detection, which flags thin walls, tricky overhangs, and unsupported areas early on, saving time and helping avoid failed prints. In fact, according to G2 Data, 92% users value it for 3D modelling tools.

Another feature users often highlight is the ability to build infill structures, such as honeycomb and gyroid patterns, directly into the model. Unlike most slicers that only offer basic infill percentages, SOLIDWORKS lets you design these as actual geometry. This is particularly useful for parts that need to hit specific strength-to-weight targets.

Simulation capabilities are also a major plus. G2 users highlight how easy it is to run stress and thermal analyses on a part before printing. It’s a valuable step for anyone producing functional components where failure isn’t an option.

I do think that SOLIDWORKS stands out for its robust engineering capabilities and precision modeling tools. Still, it’s not without quirks; the STL export process feels somewhat dated, requiring extra steps to adjust resolution settings. Reviewers also note that working with mesh-based files can be frustrating, as complex STLs or scans are harder to edit compared to platforms like Solid Edge. Even so, users value SOLIDWORKS for its reliability and professional-grade output.

I saw many reviewers also highlight SOLIDWORKS’ strong performance and integration within professional design environments. However, the licensing model remains a drawback; there’s no free version, and the cost is steep for those who only need basic CAD tools for 3D printing. Still, for engineering teams already invested in the software, most say the advanced capabilities justify the expense.

“SOLIDWORKS has a very intuitive interface for part and assembly design. It has power parametric modeling features that enable more advanced assembly/part support. The software also does a good job of exporting to various file types, whether it is.STEP for CAD sharing or.STL for 3D printing.”

- SOLIDWORKS Review, Josh L.

“The only downside I've found is the occasional slowdown and sometimes crash. Usually, that's more of a computer/graphics card issue or bad form in creating assemblies that are too large, but it is a challenge sometimes.”

- SOLIDWORKS Review, Ryan S.

Tinkercad is probably the most beginner-friendly 3D printing software out there, and I wanted to see if it was just for kids and hobbyists or if it could handle more serious printing needs. Unlike the other tools I evaluated, which focus on parametric modeling, industrial workflows, or advanced simulation, Tinkercad is all about accessibility.

It’s a web-based program that lets you drag, drop, and combine shapes to create 3D models, making it ideal for individuals who have never worked with CAD before.

One thing G2 reviewers often mention about Tinkercad is how fast it is to get started. There’s no software to install and no steep setup, just open a browser, create an account, and you’re designing within minutes. For users intimidated by traditional CAD tools, Tinkercad’s simplicity is a breath of fresh air.

The built-in shape library is another highlight. It includes geometric solids, text, and even basic mechanical parts like gears, which makes creating simple objects, such as keychains, nameplates, and enclosures, quick and intuitive. Unlike tools that rely on constraints or precise parametric inputs, Tinkercad is entirely visual: you drag, resize, and combine objects freely. It’s no surprise that it’s a favorite in classrooms and maker spaces.

The block-based coding feature also stands out. It introduces beginners to procedural modeling by allowing them to generate shapes using simple scripts. While it doesn’t offer the depth of parametric modeling seen in platforms like SOLIDWORKS or Fusion 360, reviewers say it’s a great starting point for teaching code-based design.

From reading G2 reviews, I found that Tinkercad is widely appreciated for its simplicity and ease of use, especially for beginners. That said, it definitely has its limits when it comes to advanced 3D printing processes; there aren’t precision tools for defining exact alignments, tolerances, or fit constraints. Still, most users (and I’d agree) see it as a great starting point for quick prototypes, educational use, or simple design projects.

I also noticed several reviewers mention that, since Tinkercad runs entirely in a browser, it can struggle with large or high-polygon models. Importing detailed STLs or scanned meshes often leads to lag or unresponsiveness. Even so, users appreciate how accessible it is, with no installation required, quick setup, and being perfect for quickly modeling ideas.

“I accidentally discovered TinkerCAD on a 3D printing forum. I was immediately blown away by how easy it was to set up the account and get started. It stores designs on the cloud, which can be accessed from anywhere. The tools are simple and intuitive to access. You can even import files from other software and incorporate them into your own design. Especially for regular 3D printing enthusiasts, it's an everyday tool that cannot be overlooked; it's literally like building with LEGOs. It's fun to use and is functional. If you get stuck, there's also a very nice forum with a very nice community.”

- Tinkercad Review, Anubhav M.

“Although it is very helpful and easy to use for beginners and start-ups. It could use more advanced features in the future that are currently missing to rival more design-oriented professional 3D software.”

- Tinkercad Review, Omar M.

Ultimaker Cura is one of the most widely used 3D printing software options, and I wanted to see if it actually deserves its reputation. Cura isn’t about designing models, it’s about preparing them for printing. It’s a dedicated slicing software that translates your 3D model into a set of instructions for your printer, and it’s completely free.

G2 reviewers often highlight Cura’s model preparation workflow as one of its biggest strengths. Users note that it processes STL files quickly, even with complex, high-detail models. The interface is clean and intuitive, with commonly used settings easy to access, and no need to dig through layers of menus.

Another feature that gets praise is Cura’s automatic printer detection. Reviewers appreciate how it incorporates key specifications, such as build volume and nozzle size, without requiring manual setup, which helps streamline the initial configuration process.

G2 reviewers often praise Cura for its depth of print settings, which offer over 400 adjustable parameters, ranging from layer height and print speed to cooling and acceleration. Many users find the default profiles, especially for Ultimaker printers, well-optimized and beginner-friendly. At the same time, the ability to create fully customized profiles makes it a favorite among advanced users who work with third-party machines. Reviewers frequently note that Cura provides more fine-tuning options than most free slicing software.

One standout feature mentioned often is Cura’s tree supports. Unlike traditional support structures, these organic-style supports are easier to remove and use less filament, making them ideal for delicate or complex overhangs. It's a unique addition that sets Cura apart from many other slicers.

Post-processing scripts are another highlight. Users appreciate the ability to insert custom G-code commands mid-print, enabling actions such as filament swaps, color changes, or pause-and-insert steps. These advanced controls give Cura more versatility, especially for hobbyists experimenting with multi-step prints.

From reading G2 reviews, I found that Cura earns praise for its powerful slicing features and wide printer compatibility. That said, users often mention frustration with its print time estimates; actual print durations can run hours longer than predicted, making it tricky to plan long jobs or manage queues. Still, most agree the tool’s overall performance and control make it worth the extra planning.

Reviewers also highlight Cura’s detailed customization options, but note that it can be resource-heavy. Slicing high-poly models or using advanced settings tends to slow down lower-end systems. Even so, those with capable machines say the performance trade-off is fair for the precision it delivers.

I also noticed feedback that, while Cura supports many third-party printers, it’s clearly optimized for Ultimaker hardware. Some users mention needing to manually tweak settings for non-Ultimaker machines. Still, most appreciate the flexibility and open compatibility that let them fine-tune prints across a wide range of devices.

“Cura is incredibly intuitive, which is saying something since 3D printing has a ton of variables to deal with. However, they are all laid out in a way that just makes sense. Best of all, I've never had a single "software issue" through any of my hundreds of prints. Anything that has gone wrong has been on me due to a configuration error or something with the printer itself.”

- Ultimarker Cura Review, Patrick M.

“I cannot point out any single factor that I disliked about Ultimaker Cura because I am still fairly new to 3D modeling and 3D printing. This is a widely used software, so any difficulties can be solved by posting on various forums to get feedback on any issue.”

- Ultimarker Cura Review, Shay D.

| Software | G2 rating | Free plan | Ideal for |

| Onshape | 4.7/5 | Yes | Engineers, product designers, and teams needing cloud-based collaboration. |

| Autodesk Fusion | 4.5/5 | Yes | Professionals and makers who need integrated CAD, simulation, and slicing tools. |

| Siemens NX | 4.4/5 | No | Enterprise users, aerospace, and automotive engineers needing high-precision modeling. |

| Solid Edge | 4.3/5 | Yes | Mechanical designers and professionals working with STLs and scanned parts. |

| SOLIDWORKS | 4.4/5 | No | Engineers and manufacturers requiring parametric design and advanced simulations. |

| Tinkercad | 4.5/5 | Yes | Beginners, students, and educators looking for an easy-to-use 3D design tool. |

| Ultimaker Cura | 4.7/5 | Yes | 3D printing enthusiasts and professionals needing a reliable slicing tool. |

Note: G2 Ratings are based on user reviews and are subject to change.

Have more questions? Find more answers below.

There’s no single “best” tool. It depends on your goals. For slicing, Ultimaker Cura is the go-to free option. For mechanical or engineering designs, Autodesk Fusion and SOLIDWORKS offer professional-grade precision. Tinkercad is perfect for beginners, while Siemens NX is ideal for industrial-scale 3D printing and simulation.

Yes. Onshape lets you model on any device, and Tinkercad runs fully in your browser. Most slicers, such as Cura, still require a desktop installation.

CAD software is for designing 3D models; 3D printing (slicing) software prepares those designs for printing. The slicer converts your model into printable layers and generates G-code for your printer. Some tools, like Fusion 360, combine both functions.

Siemens NX and Autodesk Fusion lead the pack with advanced simulation and topology optimization. SOLIDWORKS is another trusted choice for engineering-grade part design, especially in metal 3D printing.

Ultimaker Cura, PrusaSlicer, and Onshape all work smoothly on Mac. Tinkercad runs in any browser, while Autodesk Fusion, Blender, and Rhino 3D offer full professional functionality.

Try Tinkercad for lightweight, browser-based modeling. PrusaSlicer is efficient even on older hardware, while Cura can perform better by lowering preview quality and disabling real-time slicing.

After evaluating all these 3D printing software options, I’ve realized that there’s no one-size-fits-all solution. Some tools make designing models ridiculously easy, while others give you engineering-level precision. Some are perfect for beginners, while others feel like they expect you to have a degree in manufacturing. But no matter where you are in your 3D printing journey, there’s a tool on my list that fits.

If you’re just getting started, I’d suggest something simple and intuitive; no need to overwhelm yourself with a hundred print settings on day one. If you’re leveling up, it’s worth exploring software that gives you more control over slicing, supports, and material efficiency. And if you’re already pushing the limits of 3D printing, advanced CAD software with simulation, topology optimization, or industrial print prep might be exactly what you need.

The best way to figure out what works is to experiment, tweak, and print. The real learning comes from trial and error and a few failed prints along the way. So pick a tool, start designing, and turn those ideas into reality, one layer at a time.

Take your designs to the next level with the best 3D modeling software, as reviewed by my team.

Washija Kazim leads the SEO/AEO content strategy at G2, helping the brand stay visible across search and AI-driven discovery. Her expertise lies in turning buyer demand, SERP shifts, and performance data into content roadmaps and scalable workflows. Outside of work, she can be found buried nose-deep in a book, lost in her favorite cinematic world, or planning her next trip to the mountains.

There’s something to be said about seeing an idea or a design come to life.

by Mara Calvello

by Mara Calvello

Whether you’re a hobbyist sketching out ideas, a student learning design, or a professional...

by Samudyata Bhat

by Samudyata Bhat

We have come a long way from sketching on notepads.

by Harshita Tewari

by Harshita Tewari

There’s something to be said about seeing an idea or a design come to life.

by Mara Calvello

by Mara Calvello

Whether you’re a hobbyist sketching out ideas, a student learning design, or a professional...

by Samudyata Bhat

by Samudyata Bhat