E-commerce platforms are no longer secondary to that of brick-and-mortar stores.

In fact, having an e-commerce platform is crucial to ensure business success today. The numbers don’t lie. Global retail e-commerce sales totaled over $3.5 trillion in 2019.

The value of the market is rising year on year. Running an online store can be lucrative if you correct the vital processes. One such process is your inventory management.

At heart, e-commerce is simple. You showcase a range of products online, customers find and buy what they want, and then you deliver. What’s critical, then, is that you have the items you advertise and can get them where they need to go. That’s why getting your inventory management right is essential.

Read on, and you’ll learn all you need to know about the crucial area of your e-commerce business. We’ll discuss precisely what inventory management is and why it’s so vital. Then, we’re going to explain what you can do to streamline your inventory management and how it will save you money.

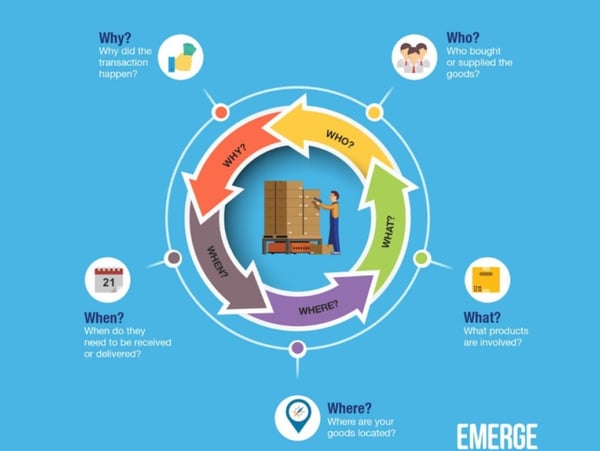

Inventory management is a business process that encompasses many elements related to the supply chain. That comprises ordering stock or components from suppliers. It also includes warehousing products and dispatching items for delivery. All the while, accurate records of where units are and how many you have, get created and updated.

It’s in the retail sector that inventory management is most vital. Retailers get driven by supply and demand. As businesses, they only succeed if they supply products that their customers demand. Having enough of the right items on hand, therefore, is fundamental to their survival.

For online retailers, superior inventory and warehouse management systems can make a profound difference. Get it right, and your firm can thrive. Get it wrong, and you may fold. Having a handle on stock and the supply chain helps companies to meet vital challenges. The following are some of the reasons why inventory management is so critical.

Overstocking can be damaging for any ecommerce firm. For smaller businesses, it can be fatal. If you have too much stock on hand, you’re wasting your valuable warehousing space. That’s room that could be utilized for more products that customers are buying. In the worst-case scenario, overstocking can also lead to having dead stock. That’s inventory that you’re never going to sell and may have to pay to dispose of.

Having too little stock can be as bad as having too much. You don’t want to run out of items that customers want to buy. That’s custom you’re giving up, simply because you got your stock levels wrong. What’s even worse is if you take orders that you can’t then fulfill. That’s called overselling and is something customers don’t forgive. 69% of consumers are less likely to use an online store again if an order gets fulfilled as little as two days late. If an order gets canceled, the percentage is far higher.

It’s not only smaller businesses that must focus on inventory management. It can be even more critical for larger organizations. Take, for instance, an online retailer with multiple warehouse and distribution channels. Keeping track of stock and orders gets exceptionally complicated. A streamlined, efficient inventory management system is a necessity.

You might think you can track and handle your inventory by hand (or with pen and paper). When your business is small, you might be right. As you grow – and that’s presumably your aim – your manual management won’t scale. It’s only a well-defined and streamlined system that can grow with your business.

Streamlining inventory management is always worthwhile. That's whether you run a new or established online store. Small improvements in your supply chain can make a big difference. By finding the right system for your firm, you can improve many processes. From logistics to customer service, you’ll see better efficiency across the board.

The following are six straightforward steps to take to streamline your inventory management. We’ll discuss each in brief, and explain how it can make a difference to your bottom line.

The first step in improving any system is ensuring you know precisely where you stand. That means taking stock – no pun intended – of how you currently track and manage inventory.

Examine your system and find its particular weaknesses. If you use manual processes, for instance, you’re almost certainly compromising speed and accuracy. What you also need to understand inside-out is customer demand for your products. Only by knowing how and when demand fluctuates, can you ensure you always have the right stock levels.

If you’ve been in business for a while, you can delve into your sales records to get this info. The best e-commerce platforms let you find this information with ease. In some cases, though, you may have to dig out paper records or search your servers. Go back as far as you can and compile data on how and when demand rises or falls. You need to look out for trends over time and the impact of different seasons or events.

As your business grows, you may opt to sell on multiple platforms, which will require third-party integrations to ensure your inventory is up to date. So when choosing your primary e-commerce platform look into how it does with third-party integrations and inventory management tools. Analyze the features and pros and cons of your e-commerce platform options to assess which one best fits your business needs and goals.

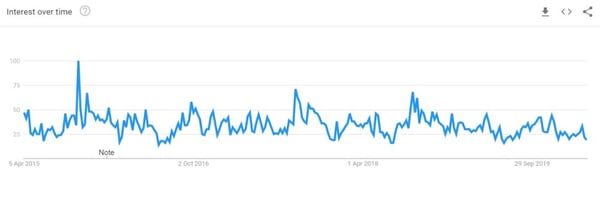

New e-commerce firms won’t have the volume of old sales data to fall back on. Google Trends, though, can prove useful in giving you something of a steer. All you need to do is plug in the name or description of the products you’re going to sell. You’ll then see an indication of how search demand for those items changes over time.

For instance, the below graph shows interest in the term ‘Raincoats’ over the past five years:

There’s lots of utility to examining customer demand. It provides insights into your most popular products, and when they’re most wanted. That will help you make fundamental decisions about inventory management. Those are choices like where to set minimum stock levels and whether to change them at certain times of the year.

Tracking demand for products shouldn’t be a one-off. You’ll also want to keep collecting data day-to-day. That way, you’ll build a database you can analyze and use to create accurate forecasts. You should use these forecasts to inform any inventory management decisions you make.

When looking to forecast demand, there are several things to keep in mind. You want to look for patterns in your sales data to answer the following questions:

Identifying those kinds of patterns helps you build an accurate forecast. They help you predict how many units you may sell in the coming weeks and months. Once you have such an estimation of future sales, you can tailor stock levels accordingly.

This type of data analytics and forecasting can help you save money in several ways:

So far, you’ve got to grips with your current inventory management. You’ve also looked at demand levels for your products and forecasted how they might look in the future. Having done those things, you’re able to make your first vital decisions.

One of the most fundamental choices involves setting your minimum stock levels. What that means is the absolute lowest level you’ll let any product’s stock reach. What you’re aiming for is to maintain as little inventory as possible, without ever failing to fulfill an order.

When you’ve set a minimum stock level, you can standardize your inventory management. By understanding demand and how long it takes to get new stock (lead time), you know precisely when to order new inventory. Factors like lead time and customer demand differ from one line to the next. That means you’ll need to set a different minimum stock level for each product.

One way to help you set those levels is by performing an ABC analysis. ABC analysis helps you understand and prioritize the product lines you carry. It involves splitting your products into three categories:

Those categories show you which lines to which you must pay closer attention. Your minimum stock level for category A products can be much lower. As a result, you need to track sales of those items more carefully. That way, you’ll ensure not to run out of the big-ticket items that likely have good profit margins.

What we’ve covered so far should have shown you how complicated inventory management can get. Getting all elements of the process precisely right is no easy task. That’s why doing everything manually isn’t the right way to progress. You don’t need to rely on staff to do stock takes or update spreadsheets by hand. Especially when there are many solutions to choose from that help automate the process for you.

Modern businesses have a whole raft of choices when it comes to software. This recent retail tech stack report offers a good overview. Amongst the array of solutions are plenty of tools to automate inventory management.

Inventory management software aids efficiency and accuracy. It tracks stock and orders automatically. That keeps any firm’s systems updated without any input needed. Business owners can even set rules within some software to automate events. For example, you can get alerts when certain products reach your minimum stock level.

There are a few ways that an automated system can save you money:

Tip: To make sure your tech stack is filled with only the best of the best, and you're not going over budget, utilize software spend optimization to your advantage.

It’s not all about software solutions to automate inventory management. There’s other technology that can help you, too. Used along with an overall system, different pieces of hardware and tools can raise efficiency across your firm.

One excellent example is that of wireless barcode scanners. With such scanners, you can keep stock records accurate from minute-to-minute. Your workers simply scan the barcodes of items coming in or going out. Your system can then update immediately.

Mobile apps integrated with inventory management systems are another useful option. Such tools are invaluable for multiple business departments. Logistics staff can log in to them to track inventory or manage shipments. Customer service staff, meanwhile, can get up-to-date stock figures while talking to customers.

Even with the best systems supported by the right tech, things can still go wrong. That's as true for inventory management as any other business process. That’s why it’s crucial to prepare for such eventualities. You’ll want contingencies in place for when an unforeseen event means you can’t proceed as usual.

A simple, yet beneficial example is to have a second and third choice supplier for every product line. That way, if your preferred vendor lets you down, you know where you can turn to get the inventory you need. You can then keep your supply chain moving and won’t have to hold extra stock to mitigate against issues.

Keeping lines of communication open with many suppliers is also sensible. If you have a good relationship with vendors, they’re more likely to be willing to dig you out of a hole if you need them to. They might, for instance, agree to dropship an order for you. That can be vital when delivery timescales are getting a little tight.

If you run an e-commerce business, inventory management is fundamental to your company. Whatever you sell, having the right stock to meet customer demand is your avenue to success. Overstock, and you’ll spend too much on warehousing or disposing of dead stock. Fail to carry enough inventory, and you’ll miss out on crucial sales.

Fortunately, there are many options to explore to streamline your inventory management. You can dig into your sales figures to make accurate forecasts. Those forecasts better inform future stocking decisions. What’s more, there are loads of software solutions that can help you. They aid you in automating the vital process and making it more accurate.

We’ve laid out some of the steps you can take to manage your inventory more efficiently. Borrow from our hints and tips those which fit your firm best. If you do, you’ll get a leg-up on your rivals and move closer to ultimate e-commerce success.

Find a way to take charge your e-commerce inventory management with the right software solutions for your needs.

Nick Shaw is the Chief Revenue Officer (CRO) of Brightpearl, a retail-focused digital operations platform for sales and inventory management software, accounting, logistics, CRM and more. He is responsible for EMEA Sales, Global Marketing, and Alliances.

Inventory is at the core of any retail business.

by Mohammed Ali

by Mohammed Ali

As you look towards advancing your career in human resources, it’s important that you do all...

by Derek Doeing

by Derek Doeing

There are an abundance of talented freelancers looking for their next gigs.

by Alina Benny

by Alina Benny

Inventory is at the core of any retail business.

by Mohammed Ali

by Mohammed Ali

As you look towards advancing your career in human resources, it’s important that you do all...

by Derek Doeing

by Derek Doeing

Never miss a post.

Subscribe to keep your fingers on the tech pulse.